- Overview

- Product Description

- Product Parameters

- Application

- Company Profile

- After Sales Service

- FAQ

Basic Info.

Product Description

Industrial single and double shaft shredder machine tire and plastic shredding machine scrap metal shredder machine price

Double shafts shredder is used for recycling and crushing pp woven bags/ plastic bags/ wood chipper with the working principle of shearing, tearing, extrusion of shafts.

Powerful Force

The shredder is also suitable to process both soft and hard material, which is applied in the field of environmental protection

for processing, resources recycling, waste incineration and etc.

The equipment adopts low-speed rotating and high torque design, with large shearing force, high cutting efficiency, low noise and

stable operation..

Parameters of Industrial single and double shaft shredder machine tire and plastic shredding machine scrap metal shredder machine price

| Model | Capacity | Power | Reducer | Dimension | Blades Diameter | Blades Thichness | Blades No. | Weight |

| YZSS-400 | 200kg/h (plastic) | 7.5kw*2 | 350 model*2 | 1.8*1*1.6m | 200mm | 20mm | 20 | 55SiCr |

| YZSS-400 | 350kg/h (plastic) | 11kw*2 | 400 model*2 | 2*1.2*1.8m | 200mm | 20mm | 20 | 55SiCr |

| YZSS-600 | 800-kg/h | 15kw*2 | 400H model*2 | 2.5*1.2*1.8m | 220mm | 20mm | 30 | 55SiCr |

| YZSS-800 | 1500kg/h | 22kw*2 | 500 model*2 | 3*1.5*2m | 280mm | 20 or 40mm | 40 or 20 | 55SiCr |

| YZSS-1000 | 3000kg/h | 30kw*2 | 650 model*2 | 4*2*2.4m | 350 or 400mm | 40 or 50mm | 25 or 20 | 55SiCr or 9CrSi |

| YZSS-1000 | 3000kg/h | 37kw*2 | 650 model*2 | 4*2*2.4m | 350 or 400mm | 40 or 50mm | 25 or 20 | 55SiCr or 9CrSi |

| YZSS-1200 | 4000kg/h | 45kw*2 | 750 model*2 | 4.8*2.2*2m | 400 or 450mm | 50 or 60mm | 24 or 25 | 55SiCr or 9CrSi |

| YZSS-1200 | 4000kg/h | 55kw*2 | 750 model*2 | 4.8*2.2*2m | 400 or 450mm | 50 or 60mm | 24 or 25 | 55SiCr or 9CrSi |

| It's also support for custom according to customer's actual demand. | ||||||||

Tyre Hard Iron Scrap Metal Press Crushing Shredder Machine Price:

1, all steel welding base, dense reinforcement plate, strong and practical;

2, thick spindle, high machining accuracy, smooth operation

3, special blade cutting tool, high speed steel, sharp edge, no deformation when heated; Hardness not less than HRC55, sharp blade, removable head;

4, professional design of knife rest, claw type knife rest spiral distribution, can disperse the force of broken material, light broken material when the impact force,

so that each piece of knife crushing shear force is greater;

5, equipped with motor overload and power supply chain protection system to ensure stable operation;

6, the motor is equipped with a protective cover, to ensure the safety of personnel in use;

7, adopt thickened body plate, feed mouth sealing design, can prevent debris flying out.

1. fixed knife: prevent material winding knife shaft;

2. Moving knife: shear material;

3. Separation sleeve: control moving knife clearance;

Shredding machine blade:

shredding machine blade after forging, annealing, heat treatment, tempering heat preservation, fine grinding on wire cutting.

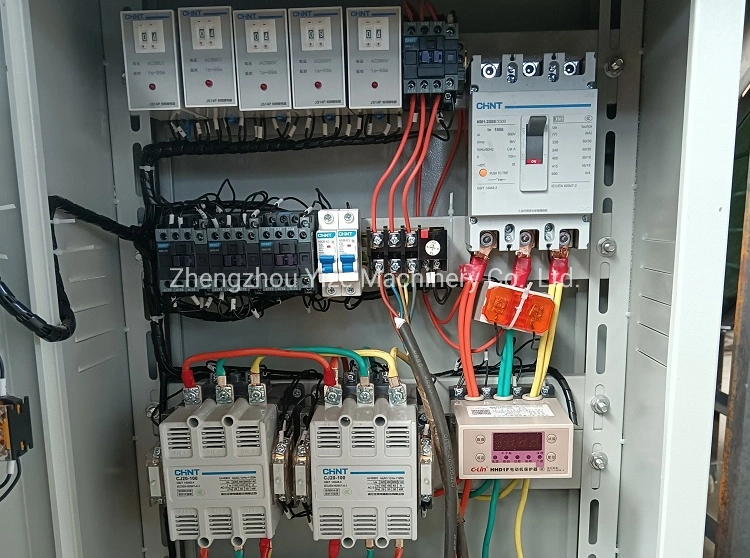

Shredding machine adopts excellent electric box, good efficiency, effectively improve service life.

Application:

1, All kinds of hollow containers: plastic beverage cans, plastic buckets, iron buckets, packing boxes, packing barrels

2, Waste appliances: TV, washing machine, refrigerator shell

3, Pipe: large pipe, pipe fittings, PE pipe

4, Waste template: wood pallet, plastic pallet, forklift pallet

5, Used tires: car tires, truck tires

6, Scrap metal: car shell, aluminum alloy, scrap cast aluminum parts, engine shell, lead and thickness of steel plate in 5mm below

7, Food waste, household waste, animal carcasses, RDF derivatives, medical waste, biological orange sticks, garden waste

8, Plastic head material, paper factory rope

Structural features:

1. Main body of crusher:

The main body of the equipment adopts high quality steel plate welding to eliminate stress treatment/integral machining to ensure the stability of the equipment in long time heavy load.

2, Moving knife/fixed knife:

The moving knife material is made of special special alloy tool steel forged blank, precision machining, multiple heat treatment and cryogenic heat treatment technology. The overall toughness and hardness can be repaired repeatedly to ensure the cutting performance and service life. Fixed knife adopts hook type installation, optimizing tool replacement function, making tool maintenance and replacement more efficient.

3, Bearing/seal:

the bearing seat adopts the split and disassembly type, can quickly remove the moving knife, fixed knife, bearing and other parts, easy to maintain and replace the tool, the unique sealing structure effectively block the contact of broken materials and grease, processing liquid materials can also protect bearings and gears, etc..

4, tool shaft:

The use of high strength heavy duty special steel processing refined, more reasonable with the tool to provide powerful power for cutting.

Service before sale

1.One-on-one exclusive customer service staff, 24 hours online.

2.Inquiry, email, message will be replied at first time.

3.Supply professional technical parameters, video picture sharing, project design.

Service on sale

1.Ensure customer payment security.

2.Ensure the customer's price is stable and reasonable.

3.Insist on quality first the production standard, every machine before leave the factory we test it ensure the quality is good.

Service after sale

1.Arrange high-efficiency delivery and safe transport.

2.Supply installation training, direction for use, maintenance instructions, techinical support, all necessary documents you need and oversea service

| MOQ | Usually 1 set, or based your order, Preferential wholesale price. | ||

| Voltage | 110V /220V /380V /415V, 50/60 HZ Single/Three phase , Customize the voltage according to your local voltage. | ||

| Guarantee | Quality guarantee term is for one year, During guarantee period, free technical support and free spare parts supply. | ||

| Payment term | T/T, Credit card, Western Union, RMB , Alipay, Wechat, Cash, E-checking, MoneyGram, L/C, etc. | ||

| Documents offer | By express:express waybill By air:airway bill By sea:B/L, commercial invoice, packing list, sales contract, CO, FE, FTA or as your request. | ||

| How to install and maintain the machine | we can teach you install or maintain the machine by video, email ,pictures.....if large project , we can arrange our engineer help you to install or maintain it in your country. If you need spare parts, we can supply for free or cost price, you pay express cost. | ||

| Assignment of engineers and training | we can supply manual book, work video, install video, pictures first, we can also assign our engineers to go abroad for installing or training machines for our users. | ||