Basic Info.

Product Description

Machine advantages

ALLWIN CNC oscillating knife cutting machine, your professional choice for cutting 5D/7D car mat.

Our machine recognize DXF/PLT format from computer, dieless cutting supply the most flexibility, it can cut any shapes and sizes quickly and perfectly.

Also, there's no need for the machine to rest or cooling, 24 hours continuous and efficient working is promised.

It can cut low-layers at one time, or cutting unlimited in length with auto feeding and cradle.

Physical cut don't react with materials, so no smoke and smell will produce during cutting.

Our machine is easy to learn and operate.

Future maintain is easy and safe.

| Model no. | ALLWIN-2513 | ||

| Working area | 2500×1300 mm(L*W) (accept customization) | ||

| Machine size | 3355x2410x1250 mm(L*W*H) | ||

| Cutting thickness | 0.1-25.0 mm (depend on material) | ||

| Cutting precision | 0.1mm | ||

| Max cutting speed | 1200 mm/s (depend on material) | ||

| Transmission interface | Ethernet | ||

| Rated power | 11KW | ||

| Working voltage | AC 110V 220V 380V±10%, 50HZ | ||

| Fixed type | Intelligent vacuum adsorption | ||

| Drive system | Servo motor, linear guide rail, rack and pinion | ||

| Safety device | Infrared sensors, 4 emergency stop buttons | ||

| Control panel | Liquid crystal display | ||

| Cutting extent | Through-cut | ||

| Standard configuration | Oscillating cutting tool, red light pointing, auto feeder | ||

| Optional configurations | Driven rotary cutting tool, punching tool (V-shape or circle shape), drawing tool, CCD camera, scanner, cradle(auto or normal), package box | ||

| Operating characteristic | Work offline; 24 hours continuous and efficient working | ||

| Cutting material | All kinds of corrugated paper, grey cardboard, KT board, PVC expansion sheet, honey comb plate, light slide, PP gum, car sticker, flag fabric, EPE foam, foam, arcylic etc. |

| Effective Cutting Area | 2500mm*1300mm 2500mm*1600mm 1100mm*1300mm 1800mm*1600mm |

Features--Vibrate Knife Cutting Machine

1.Laser emergency stop device, four laser beams, as long as the laser beam is blocked, the machine automatically stops working, to avoid the human body being touched by the moving tool head or cardboard raised and stuck the tool head. The signal line is placed in the crossbeam of the nose, so the machine runs more stably.

2.Taiwan's imported linear guideway with belt drive ensures high-speed operation of the machine while cutting smoothly to achieve rapid and accurate cutting.

3.The steel frame designed by the machine adopts high density steel plate, which is not easy to deform, and the weight of the whole machine is increased. It ensures the stability of the machine and the better effect when the machine is cut.

4.The cabinet is structured and wiring is clear, which can prevent the interference of strong electricity and weak points and maintain the stability of the machine.

5.Motors and drives adopt Taiwan Delta driver and all motors are fully digital.

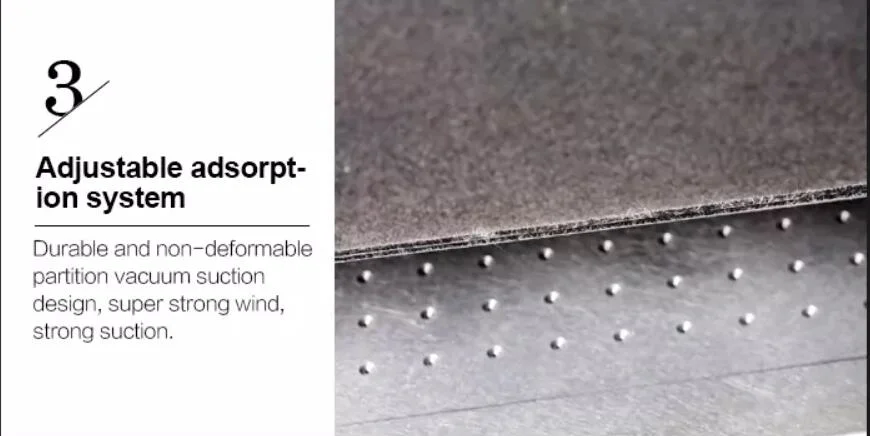

6.With modular working cylinder, the table surface has strong adsorptive force.