Basic Info.

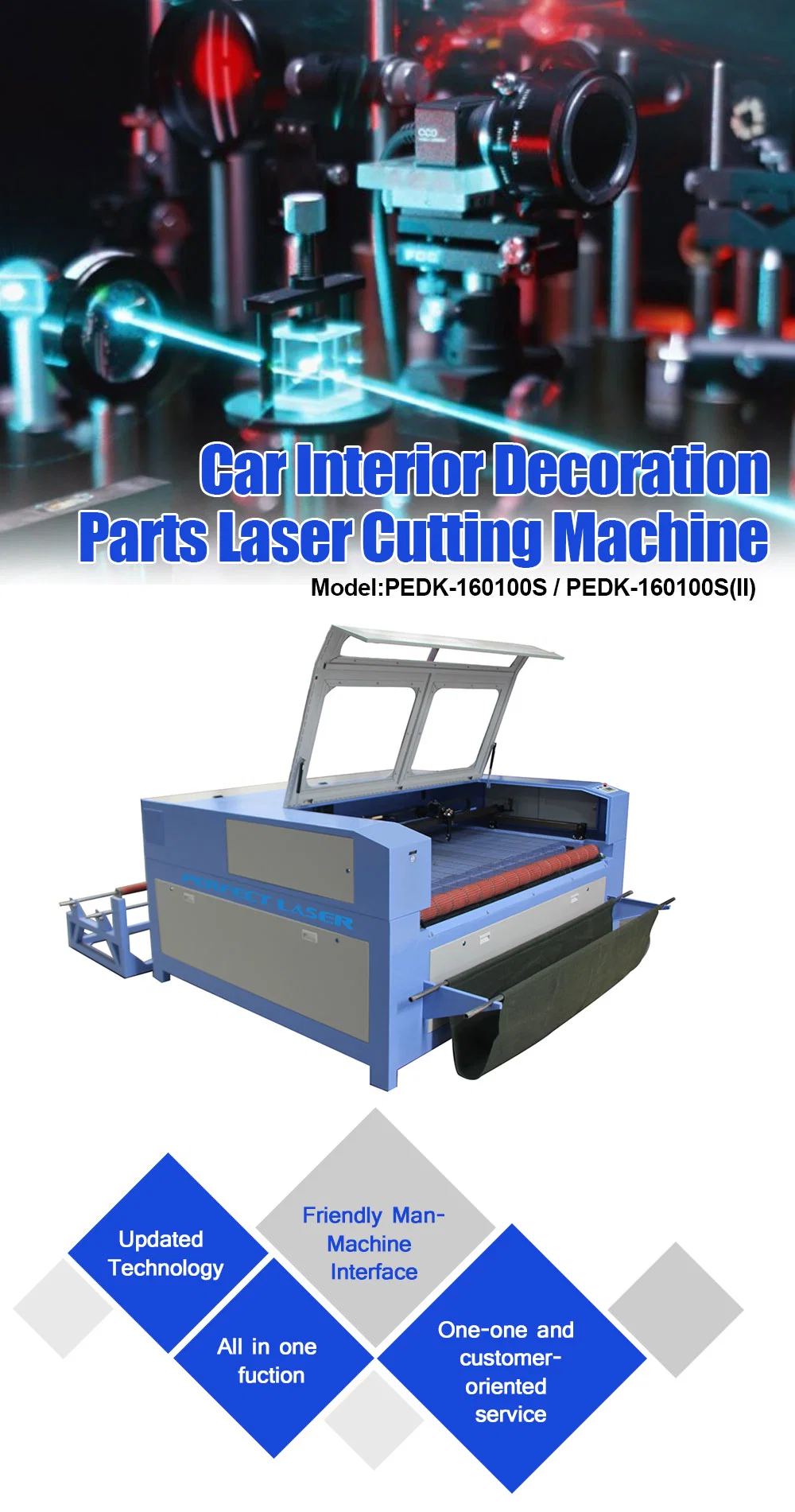

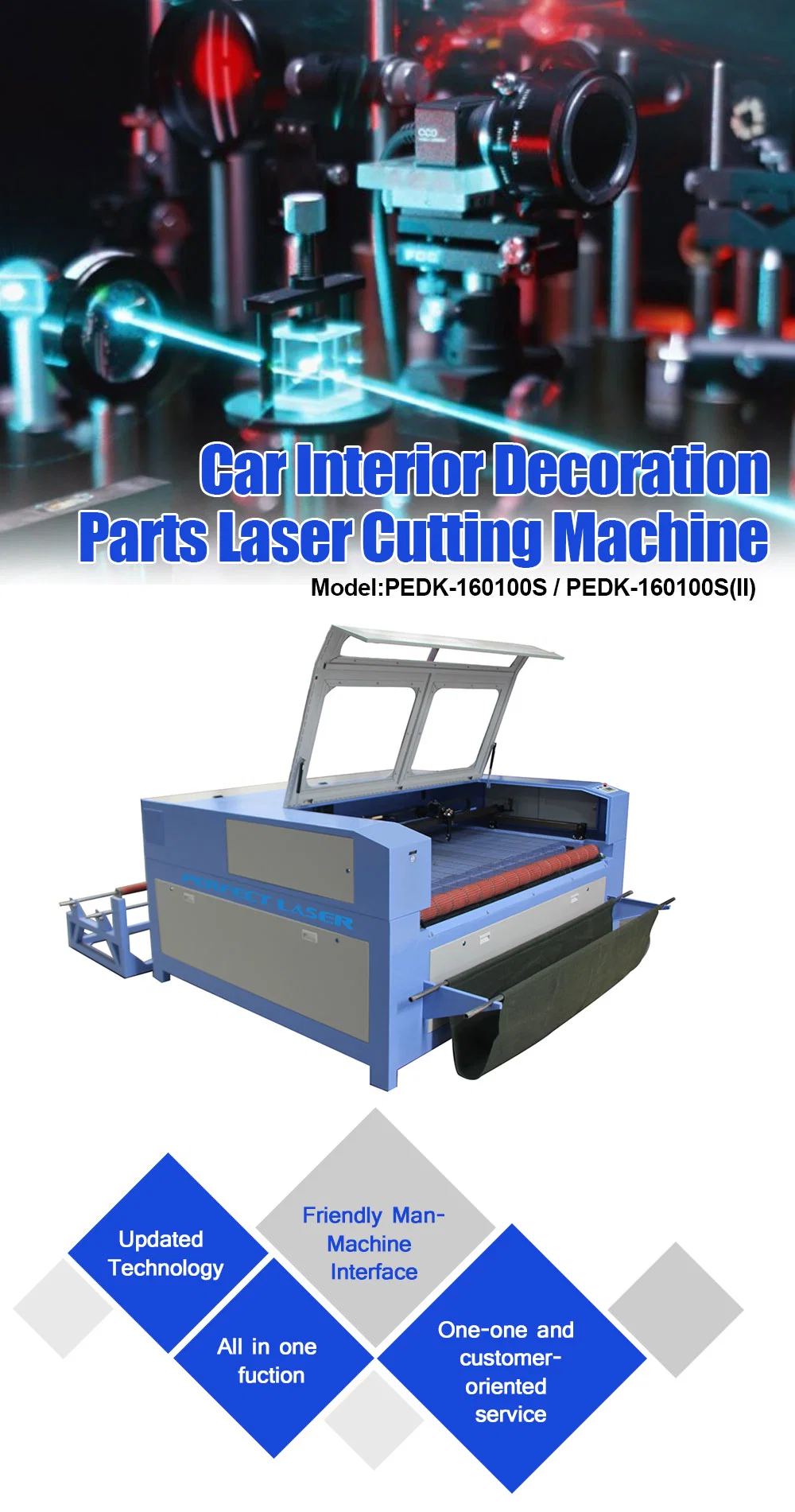

Model NO.

PEDK-160100s

Laser Technology

Laser Control Fault Cutting

Engraving Machine Type

Laser Engraving Machine

Usage

Plastic

Laser Type

CO2

Control

CNC

Current

AC

Condition

New

Type

Wood Process and Matching Equipment

Transport Package

Export Sea-Worthy Packing or Air-Worthy Packing

Specification

ISO 9001 & CE

Trademark

perfect laser

Origin

China

HS Code

84561000

Production Capacity

100 Units/ Month

Product Description

Acrylic/Plastic/Wood /PVC Board/1600*1000 CO2 Laser Cutting Machine

Model:PEDK-160100S

Product Introduction

Perfect Laser is a world leading manufacturer for carpet cutters.

This carpet cutters is specially designed for carpet cutting and related auto-car interior decoration materials. The carpet cutters can do cutting process for various kinds of car interior decoration materials like leather, fabric, cotton, plastic, rubber items, etc.

Product Features

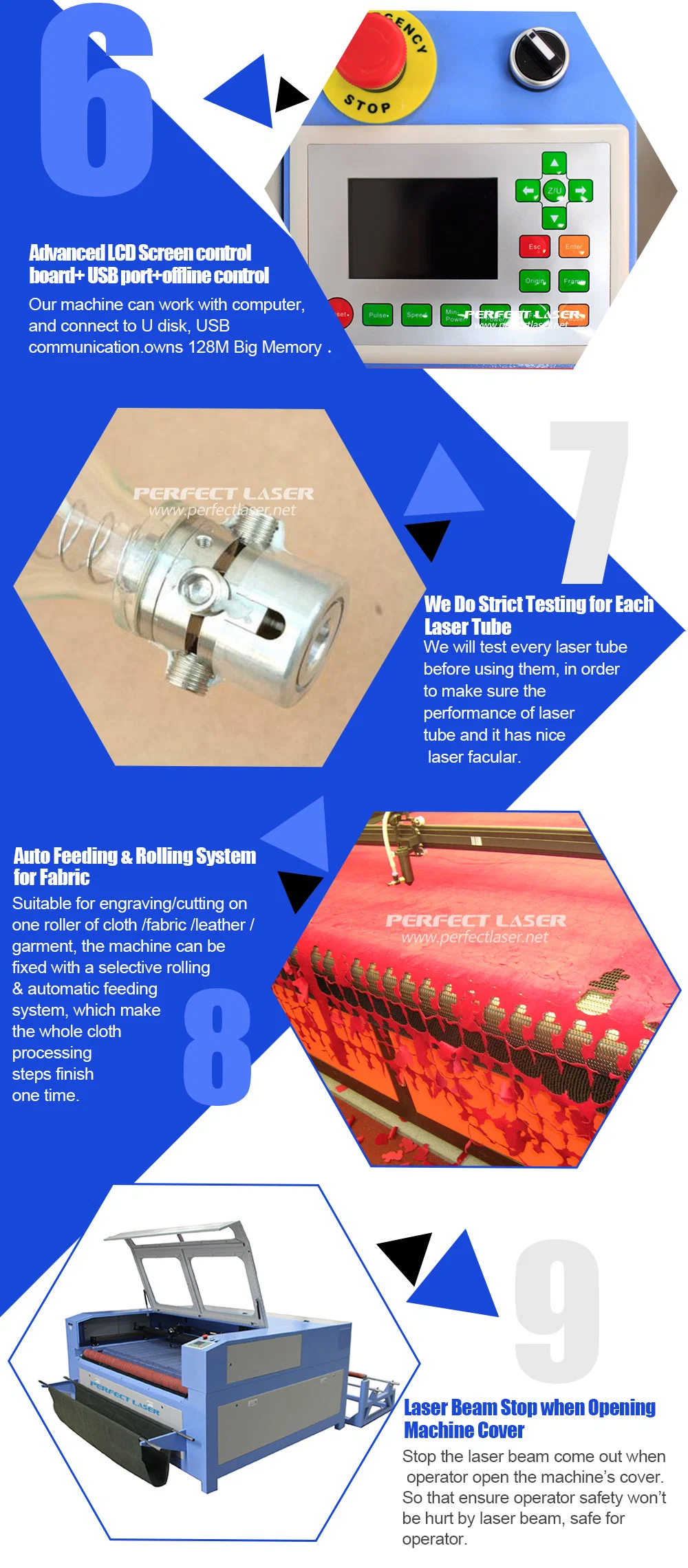

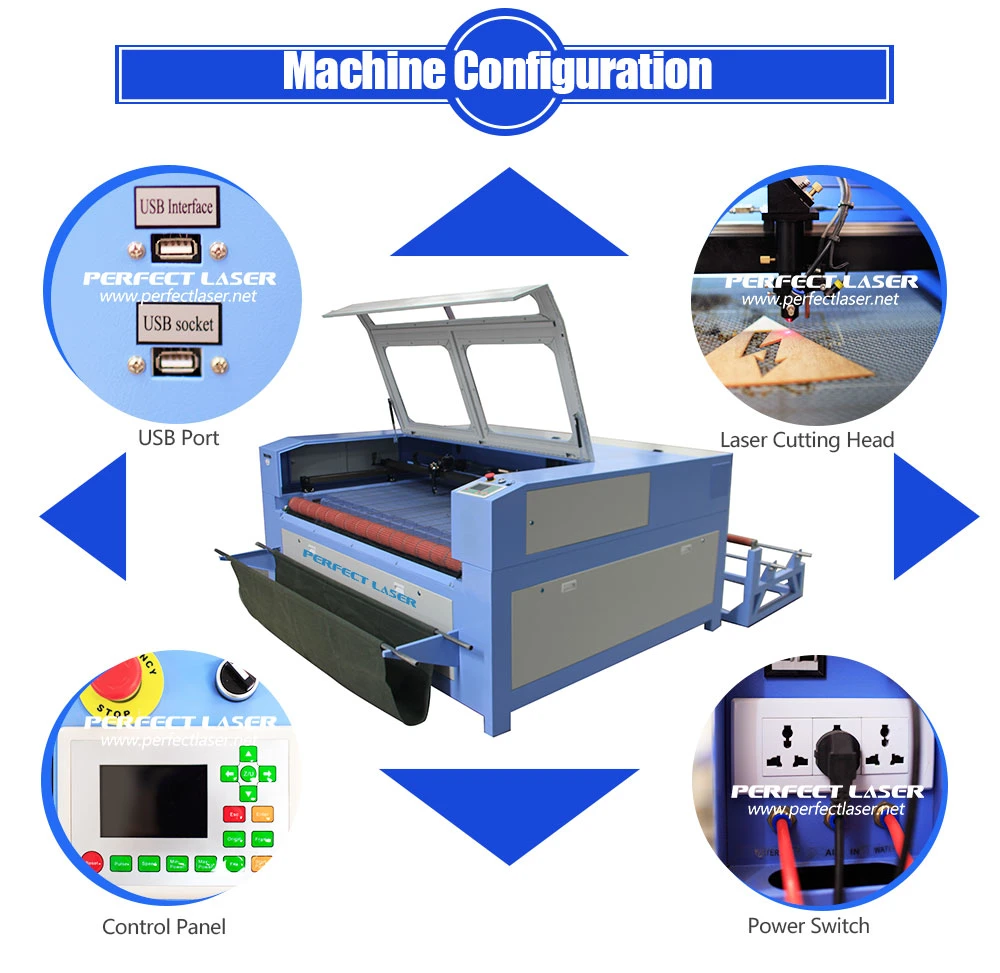

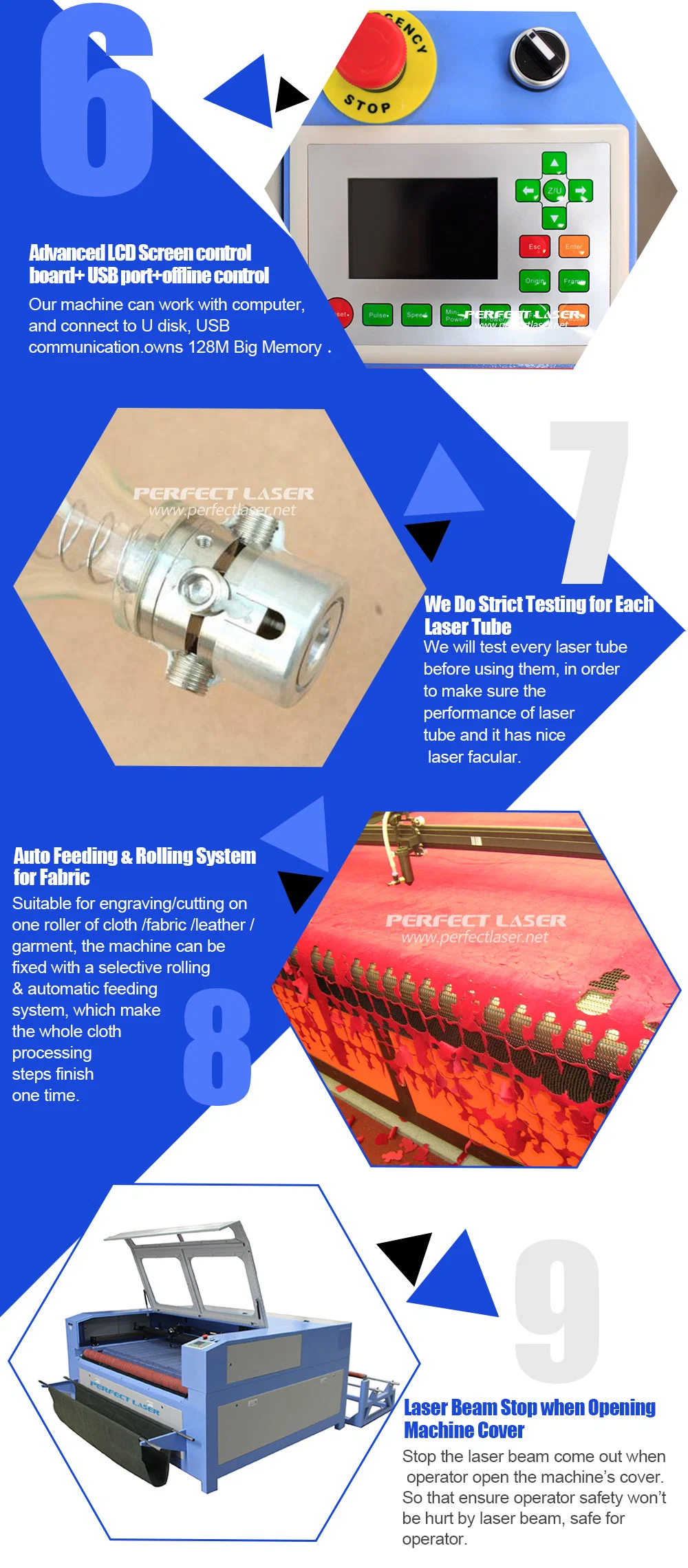

1. Equip with super working table and auto feeding system, which can do continuous feeding and precision cutting.

2. Continuous stitching function. The uncompleted cutting graphic on one material will be automatically deferred to the next material. It can cut inner parts and frame parts for one graphic at the same time by just feeding once. Intelligent typesetting system get the most effective and rational use of materials.

3. Continuous cutting function when power off. Cutting device can automatically memory cutting status when power off, machine can continue cutting after power on.

4. Equip with mini air compressor and air pump

5. Equip with Imported focus lens and mirrors, fine laser beam, strong laser power, avoiding laser power attenuation when cutting caused by optical transmission problems using traditional laser equipment.

6. Adopt strong cooling industrial-grade equipment to ensure a long operating cycle when the water temperature is always kept cold state, the laser tube light stability, and to ensure that the laser tube life;

7. Adopt Taiwan Hiwin precision linear square rails, to ensure the smooth operation of the laser head, high-speed, no jitter, having slit small, fast, high accuracy;

8. Easy operate, more humane design, users are more likely to start with;

9. Increase the added value of products. Laser cutting is not required pattern cloth version, you can freely copy crop patterns, especially for revision requirements. In the process, a laser cutting, drilling and carving and other innovative technology integration which greatly improve the value-added products.

10. Improve production efficiency. You can roll the entire fabric automatic cutting, automatic cutting, on the basis of the production process at one go. One end of a single laser cutting machine out of the material to meet the five skilled workers sewing production.

11. Save the provincial labor, and material. Because the laser is intelligent analog layout, simple, requiring workers to operate only need to know the computer. When cutting leather for leather car seat covers also avoids bad dermis, thus improving the cutting quality, reducing leather waste.

Product Application

Applicable Material:

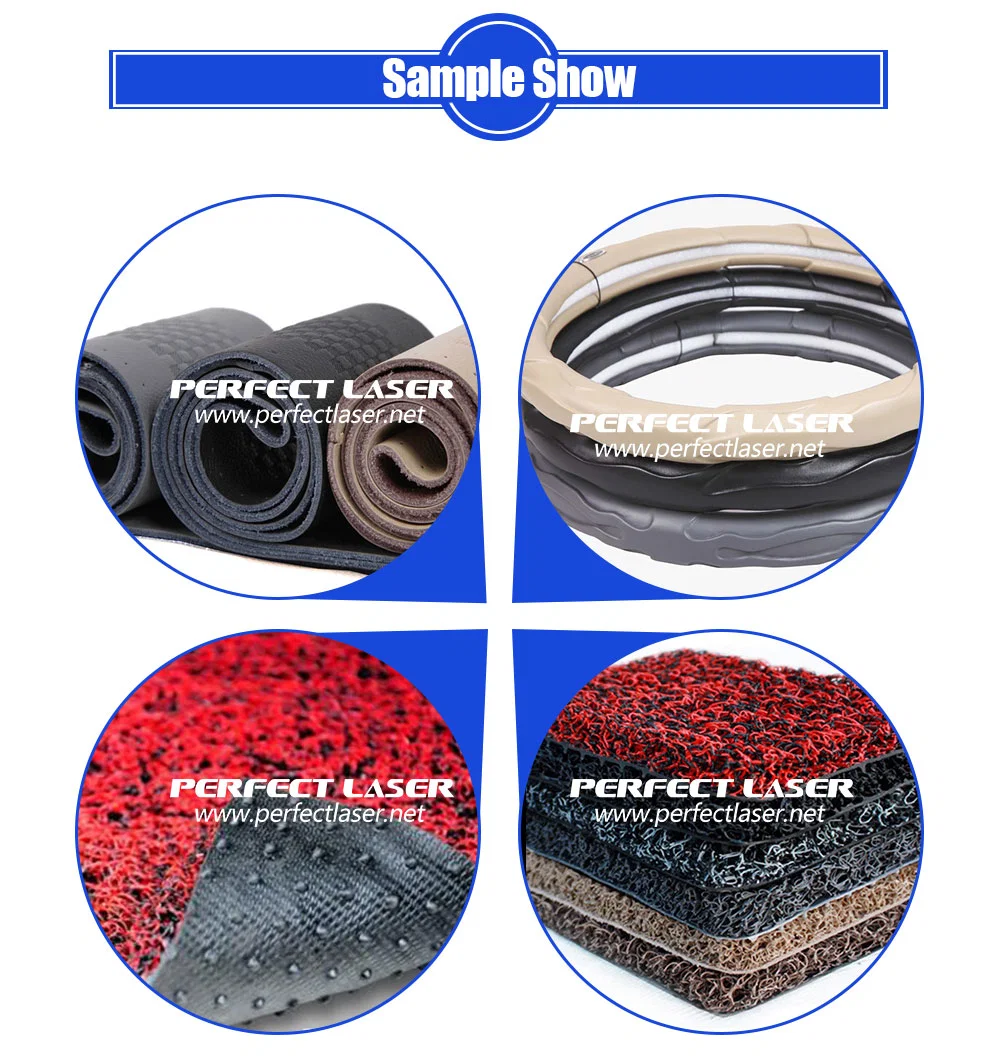

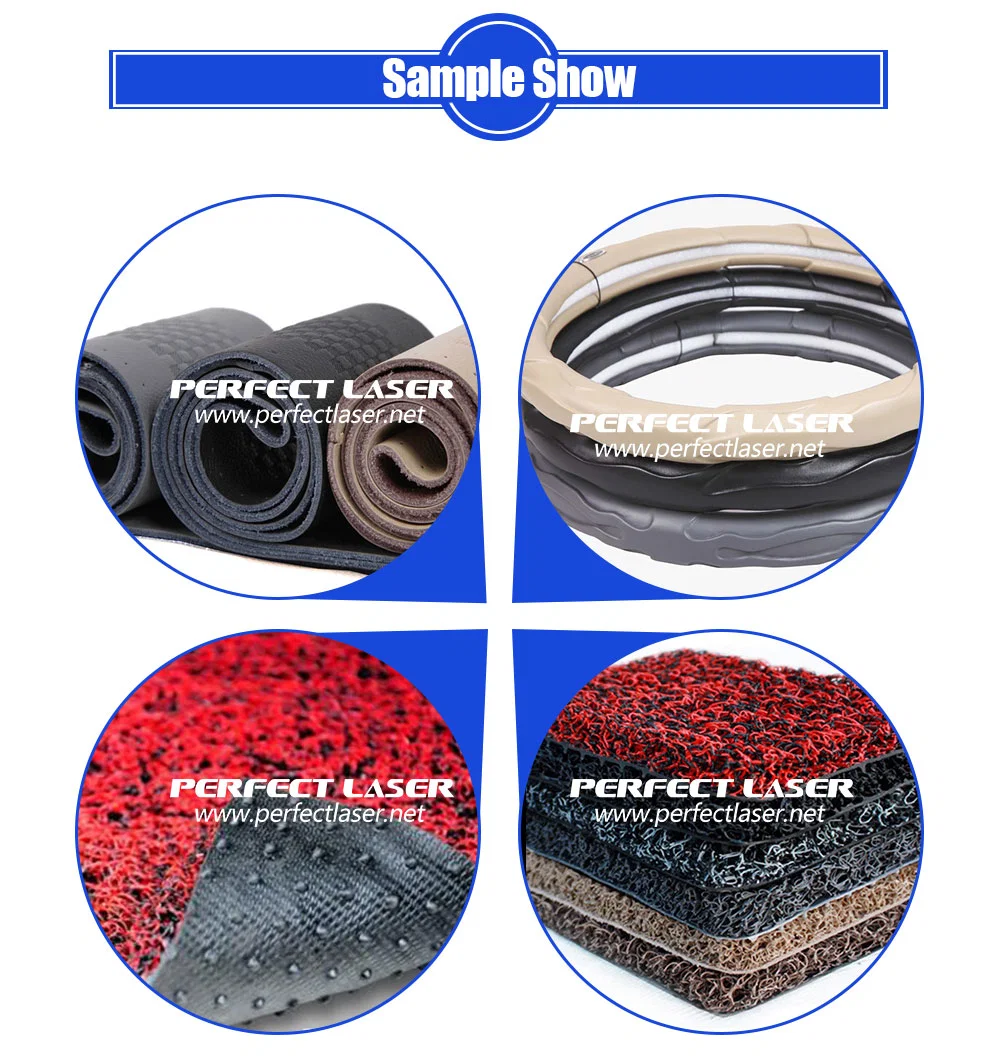

It is widely used to cutting car interior seat cushion, seat cover, car seat covers, car MATS, car cushion, car flexible fabric supplies a variety of seating cushion material cutting, including non-woven, polypropylene, blending, leather, composite, PU artificial leather, wool fabrics, woollen, ice silk, linen, peach skin,, cloth, leather, PU, microfiber, EVA, XPE composite leather, leather, sponge, sponge + cover + composite leather leather, PVC floor MATS, silk MATS.

It can also cut flexible fabrics, such as: luggage, ski suits, safeguarding supplies, swimwear, sportswear, tents, sofas, curtains, textiles and clothing.

Applied Industry:

Suitable for car upholstery, seat covers, various format carpets, carpet in front of the machine, the long blankets and other cutting, carving, parquet.

It's also called laser engraving plastic,laser carving machine,laser etching machine for sale.

Technical Data

Remark :

1.Payment terms: T/T, L/C, West Union,Alibaba Escrow.

2. Delivery lead time: 7-10 working days after receipt of the advance payment.

3. Delivery method: by sea or air shipment.

4. Packing: compound wooden cases with exporting standard

Training&Service:

1. 12months Gurantee Period;

2. Free Online Consulting Service

3. Free Operation Tranining in our factory;

4. Detailed Operational Manual &Traning CD in English Version

5. Guarantee of Quality and After Sales-Service:

The guarantee period of quality shall be 12 months counting from the date on which the commodity arrives at the port of destination. Except the artificial damage and wearing parts, we are responsible for offering the fittings free of charge during the guarantee period, but you must send the damaged fittings to us by courier with your charge before we send back the alternative fittings to you. After the guarantee of quality period, the parts required to repair or change, if any, shall be paid.

Please advise us the following information, then we can recommend you the most suitable model, right now, don't hesitate to contact -China Perfect Laser!

1):The exact material you want to engrave/cut? (wood, acrylic, cloth, fabric, leather, rubber, paper, plastic, marble....)

2):The cutting depthon above materials?(max thickness, 3 mm, 6 mm, 15 mm, 20 mm....)

3):The working area you demand? (max dimension of material, width*length, 600*400 mm, 900*600 mm, 1300*900 mm,1600*1000mm...)Working area and laser power can be customized.

4)After cut/engrave, what will be the material used for? (application)

5)Are you an end user or reseller?

Perfect Laser is a world leading manufacturer for carpet cutters.

This carpet cutters is specially designed for carpet cutting and related auto-car interior decoration materials. The carpet cutters can do cutting process for various kinds of car interior decoration materials like leather, fabric, cotton, plastic, rubber items, etc.

Product Features

1. Equip with super working table and auto feeding system, which can do continuous feeding and precision cutting.

2. Continuous stitching function. The uncompleted cutting graphic on one material will be automatically deferred to the next material. It can cut inner parts and frame parts for one graphic at the same time by just feeding once. Intelligent typesetting system get the most effective and rational use of materials.

3. Continuous cutting function when power off. Cutting device can automatically memory cutting status when power off, machine can continue cutting after power on.

4. Equip with mini air compressor and air pump

5. Equip with Imported focus lens and mirrors, fine laser beam, strong laser power, avoiding laser power attenuation when cutting caused by optical transmission problems using traditional laser equipment.

6. Adopt strong cooling industrial-grade equipment to ensure a long operating cycle when the water temperature is always kept cold state, the laser tube light stability, and to ensure that the laser tube life;

7. Adopt Taiwan Hiwin precision linear square rails, to ensure the smooth operation of the laser head, high-speed, no jitter, having slit small, fast, high accuracy;

8. Easy operate, more humane design, users are more likely to start with;

9. Increase the added value of products. Laser cutting is not required pattern cloth version, you can freely copy crop patterns, especially for revision requirements. In the process, a laser cutting, drilling and carving and other innovative technology integration which greatly improve the value-added products.

10. Improve production efficiency. You can roll the entire fabric automatic cutting, automatic cutting, on the basis of the production process at one go. One end of a single laser cutting machine out of the material to meet the five skilled workers sewing production.

11. Save the provincial labor, and material. Because the laser is intelligent analog layout, simple, requiring workers to operate only need to know the computer. When cutting leather for leather car seat covers also avoids bad dermis, thus improving the cutting quality, reducing leather waste.

Product Application

Applicable Material:

It is widely used to cutting car interior seat cushion, seat cover, car seat covers, car MATS, car cushion, car flexible fabric supplies a variety of seating cushion material cutting, including non-woven, polypropylene, blending, leather, composite, PU artificial leather, wool fabrics, woollen, ice silk, linen, peach skin,, cloth, leather, PU, microfiber, EVA, XPE composite leather, leather, sponge, sponge + cover + composite leather leather, PVC floor MATS, silk MATS.

It can also cut flexible fabrics, such as: luggage, ski suits, safeguarding supplies, swimwear, sportswear, tents, sofas, curtains, textiles and clothing.

Applied Industry:

Suitable for car upholstery, seat covers, various format carpets, carpet in front of the machine, the long blankets and other cutting, carving, parquet.

It's also called laser engraving plastic,laser carving machine,laser etching machine for sale.

Technical Data

| Model | PEDK-160100S One head | PEDK-160100S(II) Double head | PEDK-160260S One head | PEDK-160260S(II) Double Head |

| Processing table size | 1600mm*1000mm | 1600mm*1000mm | 1600mm*2600mm | 1600mm*2600mm |

| Equip Rolling and Automatic Feeding System | ||||

| Laser model | Sealed CO2 laser tube | |||

| Processing table | work platform | |||

| Laser power | 150w (optional 100w 130w) | |||

| Machine power | 3KW | |||

| Cutting Speed | 0-72000MM/Min | |||

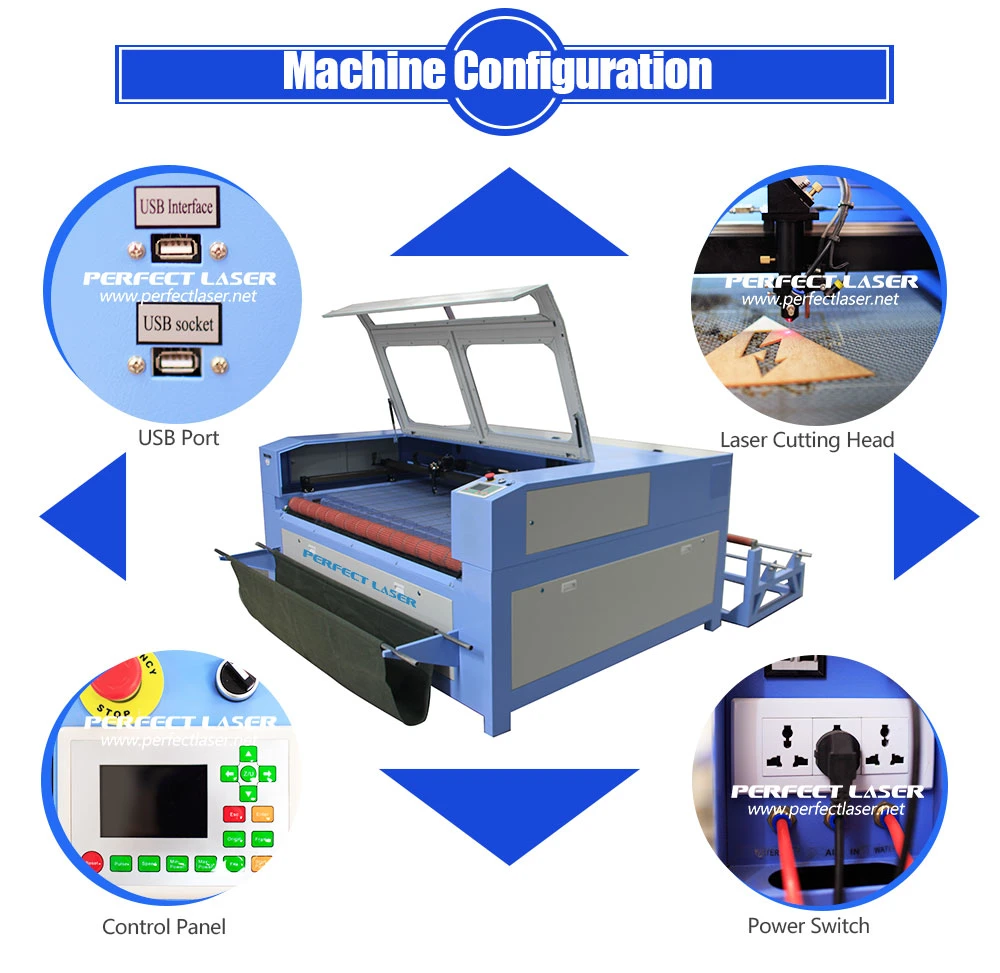

| Interface port | USB ports | |||

| Cutting thickness | 0.3-20mm | |||

| Workhumidity | 5-95% No Condensation | |||

| Controlling Mode | CNC Professional Control System | |||

| Cooling Mode | Water Cooling and Protect System | |||

| Working Voltage | AC220V±10% 50HZ | |||

| Assist Equipment | CW-5000 Water Chiller with temperature protection function, turbine dust exhauster, oil-water separator, silent air compressor | |||

| Power Controlling Mode | Laser Energy Combining Movement Control System | |||

| Control Software | Original Perfect Laser's Engraving & Cutting Software | |||

| Support Graphics Formats | BMP, HPGL, JPEG, GIF, TIFF, PCX, TAG, CDR, DWG, DXF Compatible HPG Order To Support DXF, WMF, BMP, DXT | |||

Remark :

1.Payment terms: T/T, L/C, West Union,Alibaba Escrow.

2. Delivery lead time: 7-10 working days after receipt of the advance payment.

3. Delivery method: by sea or air shipment.

4. Packing: compound wooden cases with exporting standard

Training&Service:

1. 12months Gurantee Period;

2. Free Online Consulting Service

3. Free Operation Tranining in our factory;

4. Detailed Operational Manual &Traning CD in English Version

5. Guarantee of Quality and After Sales-Service:

The guarantee period of quality shall be 12 months counting from the date on which the commodity arrives at the port of destination. Except the artificial damage and wearing parts, we are responsible for offering the fittings free of charge during the guarantee period, but you must send the damaged fittings to us by courier with your charge before we send back the alternative fittings to you. After the guarantee of quality period, the parts required to repair or change, if any, shall be paid.

Please advise us the following information, then we can recommend you the most suitable model, right now, don't hesitate to contact -China Perfect Laser!

1):The exact material you want to engrave/cut? (wood, acrylic, cloth, fabric, leather, rubber, paper, plastic, marble....)

2):The cutting depthon above materials?(max thickness, 3 mm, 6 mm, 15 mm, 20 mm....)

3):The working area you demand? (max dimension of material, width*length, 600*400 mm, 900*600 mm, 1300*900 mm,1600*1000mm...)Working area and laser power can be customized.

4)After cut/engrave, what will be the material used for? (application)

5)Are you an end user or reseller?

Any interest? Welcome to contact me now!

| Perfect Laser Co., Ltd. (China) |

| Ms. Sophie / Sales Manager < Technology Creates Perfect> |

| Cell:0086 136 5988 3308 |

| Website: perfectlaserco.en.made-in-china.com |

| Tel / Fax: 0086-27-8678-1986 / 8677-5865 |

| Working Hours: 8:30 am-17:30 pm at Beijing time (Mon~Fri) |

| Addr: HengRuichuangzhi Technology Park, No.13 YangQiaohu Road, Jiangxia District, Optical Village, Wuhan, Hubei, China(430200) |

Thanks for watching!

Welcome to contact us for further information!