- Overview

- Product Description

- Packaging & Shipping

- Fabrication

- Company Profile

- Certifications

- Business Negotiation

- Hot Selling Products

- FAQ

Basic Info.

Product Description

Introducing our PU Foam Insulation Panel, the perfect solution for your HVAC duct system! This panel is made up of Polyurethane (PU) insulation foam and aluminum foil on both sides, making it not only energy-saving but also environmentally friendly.

Compared to traditional galvanized Iron (steel metal) ductwork, our Pre-insulated HVAC Duct offers a superior performance with its light weight and robust system. The installation process is simple and requires only a single fix, saving you time and money. It's no wonder that our product has become increasingly popular all over the world. Depending on your specific application or project requirement, the facing of the PU panel can be 80micron aluminum foil, 200micron aluminum sheet, or pre-painted GI sheet.

Choose our PU Foam Insulation Panel for a reliable and efficient HVAC duct system that meets your needs while also contributing to a greener environment.

Technical Data

| Property | Standard | Specification |

| Thickness | 10/15/20/25/30/40mm | |

| Size | 3950/2950/2900*1200mm | |

| Foam Density | 50 kg/m³ | |

| CFCs and HCFCs | Head space GC/MS | Free |

| Thermal Conductivity | ASTM C518-17 | 0.02 W/m.k |

| Fire Rating | BS 476 Part 6&7 | Class 0 |

| Compressive Strength | ASTM D1621-16 | 202 KPa |

| Tensile Strength | ASTM D1623 | 423 KPa |

| Water Absorption | ASTM C209-15 | 0.36% |

| Dimension Change | ASTM D2126 | 0.30% |

| Maximum Wind Velocity | 13-20 m/s | |

| Maximum Running Temperature | 80 °C |

PU duct panel with both sides embossed 80micron aluminum foil is suitable for internal use. For external environment, it is better to choose that with 200 micron thickness aluminum sheet or pre-painted GI sheet, as the bending / compressive strength is better. The smooth aluminum foil facing is used for clean room project, such as hospital and pharmaceutical engineering.

PU PIR foam duct panel is packed by plastic film or carton, 10 sheets per package. The quantity of one container can be loaded depends on the size and thickness that customer required. Here are some examples of our normal specification:

40'HQ container: 3950×1200×20 mm, 660 sheets 2950×1200×20 mm, 880 sheets

20'GP container: 3950×1200×20 mm, 200 sheets 2900×1200×20 mm, 400 sheets

Fabrication of Pre-insulated Air Duct including: tracing, cutting, gluing, folding, taping, profile&reinforcement, sealing. During this proceduce, some accessories are needed: cutter, profile (flange), tape, aluminium reinforcement section bar, silicone sealant, and manual bending machine. We also supply these related accessories.

We have attended many RHVAC Exhibitions in different countries, such as Thailand, Australia, Pakistan and so on. Many customers also come to visit our factory. We warmly welcome all customers and friends to visit our factory for cooperation.

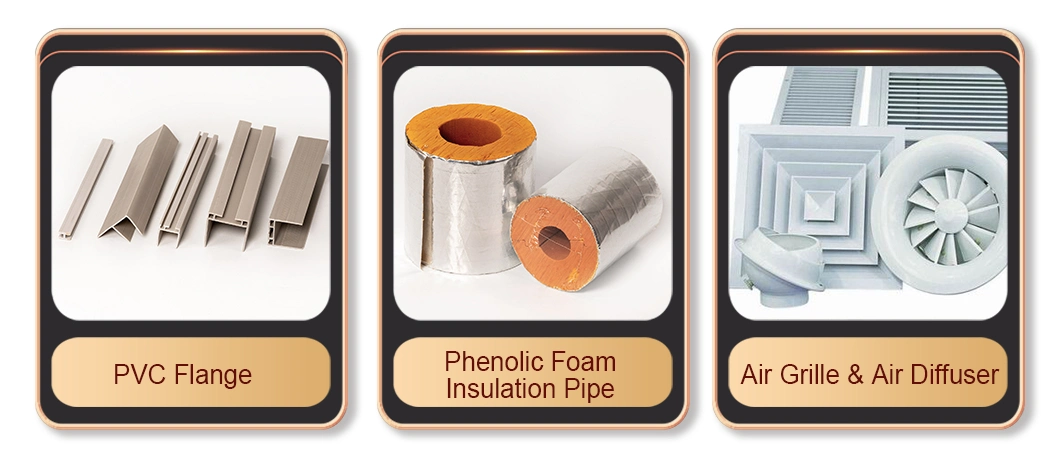

Hot seling products including: PIR/PU duct panel, Phenolic duct panel, pre-insulated tool box, PVC flange, Phenolic foam insulation pipe and air grille& air diffuser.

(1) Can you send samples of Pre-insulated duct panels?

Yes, free small sample pieces can be sent out. You just need to pay the express fee.

A.You can provide your courier account, like DHL or FEDEX or TNT.

B.You can call your courier to pick up at our office.

C. You can pay us the express charge by T/T or by PAYPAL etc..

(2) How many sheets can put in one 40ft container?

40ft container usually can load 660 sheets of size 3950*1200*20mm, or 880 sheets of size 2950*1200*20mm.

(3) What is your delivery date, and from which sea port?

For one 40ft container, we can usually delivery it within one week after receiving the deposit.

We usually ship it from Xiamen Port, China, which is in Fujian Province.