Basic Info.

Model NO.

DO1625S

Condition

New

Control

Automatic

Application

Paper, Plastic, Leather, Fabric, Epf, EVA, Foam, Sponge, Leather, Cloth...

Power Source

Electric

Layout

Vertical

Working Area

1600*2500mm

Method of Fixing Material

Vacuum Suction

Transmission

Rack

Driving

Servo

Transport Package

Wood Crate

Specification

1625

Trademark

FLYING

Origin

China

HS Code

84411000

Production Capacity

100PCS/Month

Packaging & Delivery

Package Size

228.00cm * 300.00cm * 160.00cm

Package Gross Weight

1300.000kg

Product Description

Oscillating Knife Laser CNC Digital Cutter for EVA EPE PE PVC Foam Sponge Cotton Honeycomb Corrugated Cardboard Paper Package lining Cutting

Introductions:

Introductions:

Our digital EVA foam oscillating knife cutting machine is widely used in packaging, crafts, toy manufacturing, advertising, and other industries. Only need to transfer the designed graphics to the computer, our digital oscillating knife cutting machine can automatically and accurately cut a variety of foam materials, such as EPE, EVA, XPE and other foam materials. No need for molds, high processing accuracy, high efficiency, neat and smooth cutting edges, to meet the cutting requirements of complex graphics.

It can be equipped with different types of oscillating cutters to meet the requirements of cutting foams of different thicknesses and hardnesses and can cut EPE foams up to 100mm thick.

Specifications:

| Model | DO1625S | |||

| Working area | 1600mm*2500mm (Support customization) | |||

| Operation properties | Online / offline operation; continuous cutting with high efficiency, 7*24 with zero downtime | |||

| Safety device | Infrared adopted; sensitive response; safe and reliable | |||

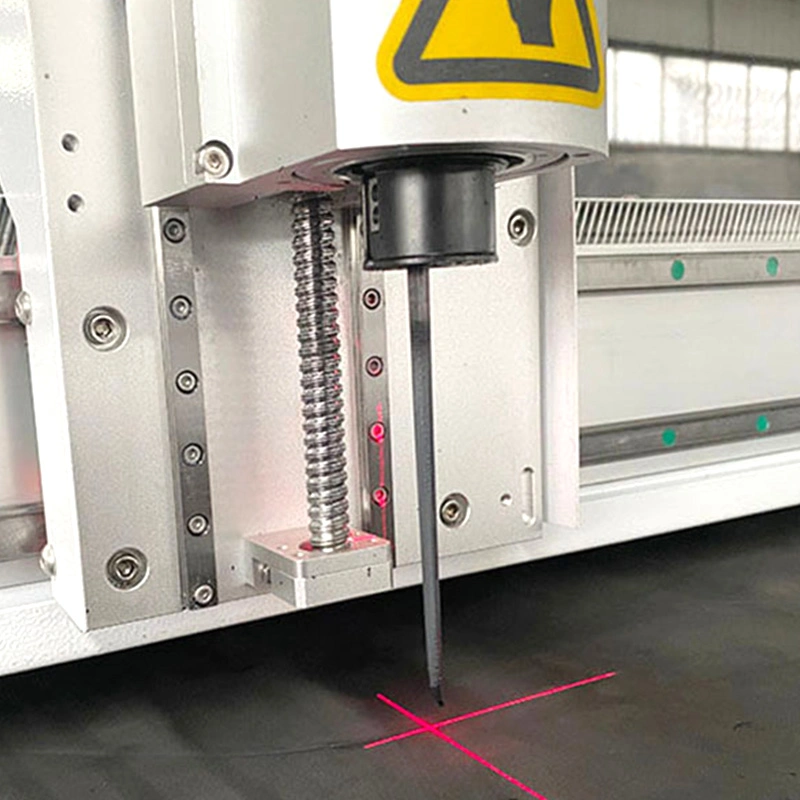

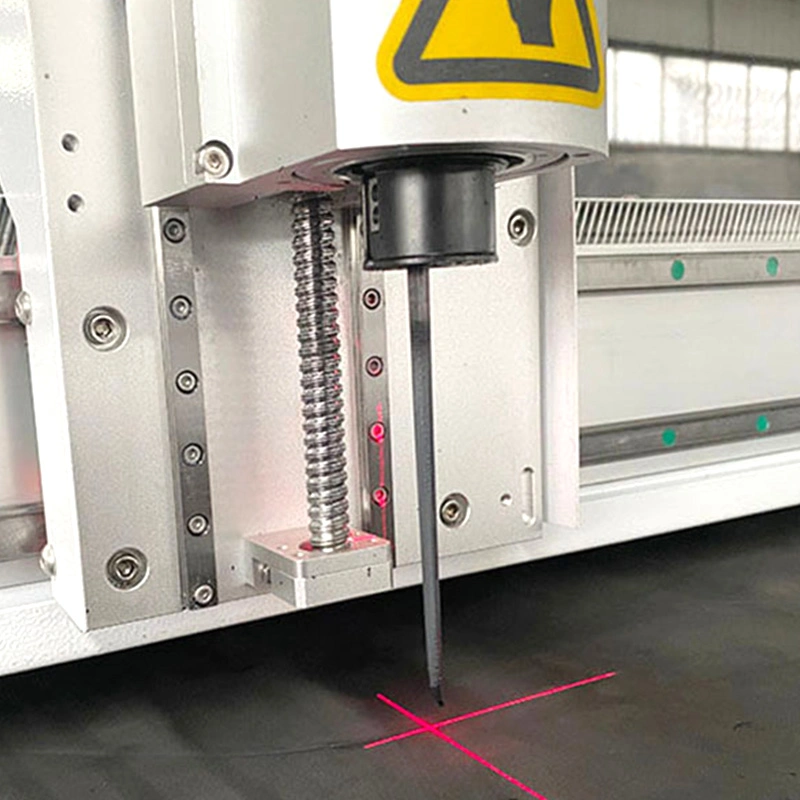

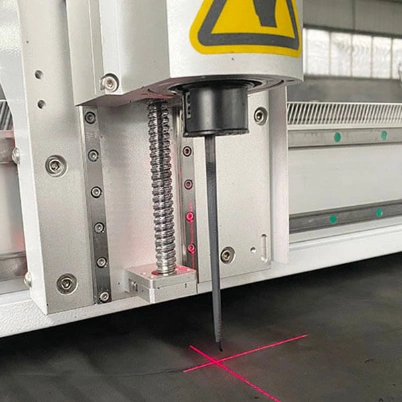

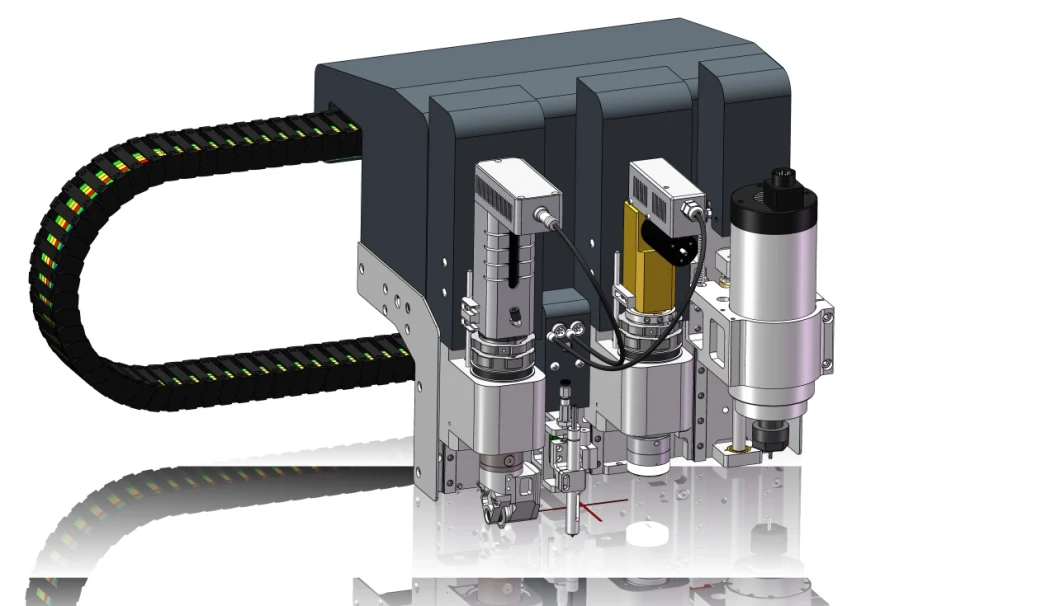

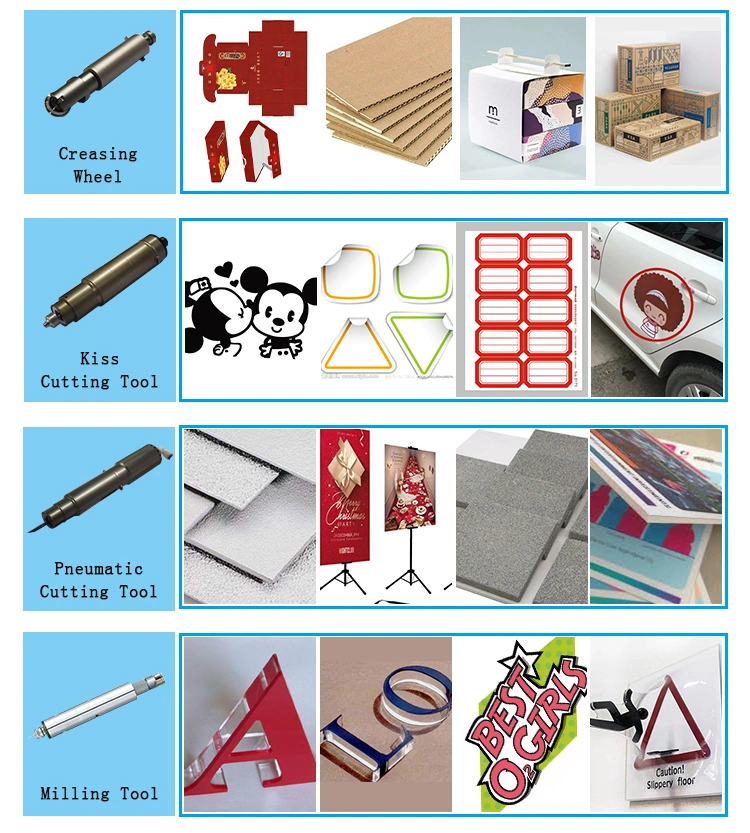

| Multi-function tool | Oscillating knife full cutting tool, Pneumatic cutting tool, Drawing tool, cursor positioning, camera positioning edge cutting, V-groove various angle cutting | |||

| Applicable materials | EPE,EVA, EPS, XPE, EPP, EPS, PET, PE, Polyethylene foam,knitted material, tatting material, fur, PU leather, jean demin, canvas, artificial leather, diablement fort,microfiber leather,flannel, etc | |||

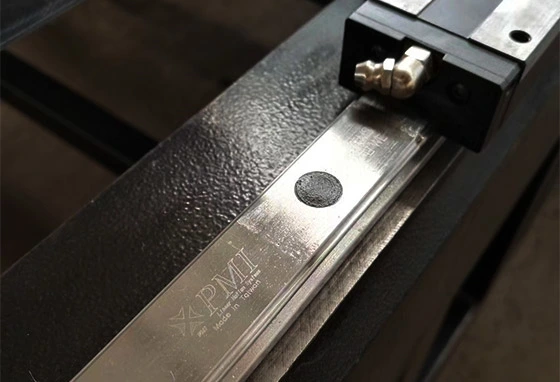

| Transmission system | Japan Panasonic servo motor + precision reducer + Taiwan HIWIN guide rail + grinding rack | |||

| Fixed mode | Vacuum adsorption | |||

| Precision | ±0.01mm | |||

| Cutting speed | 0-1500mm/s(Set according to material) | |||

| Cutting thickness | Standard cutting height: ≤45mm, customizable maximum cutting height 110mm | |||

| Support file format | AI,PLT,DXF, DWG | |||

| Rated power | 11KW | |||

| Rated voltage | 380V±10%/220V±10% Optional | |||

| Control System | Chinese English and Spanish LCD touch screen | |||

Machine Details:

Colorful LCD touch operation panel supports world multilingual kinds of languages, with more intuitive operation interface, which can directly input processing data, set processing speed and knife depth, support screen automatic protection, and protect processing data,feature-rich and user-friendly operation.

Foam CNC cutting machine uses vibration cutting technology, the cutting tool is a tungsten steel blade. Up to 100mm foam can be cut.

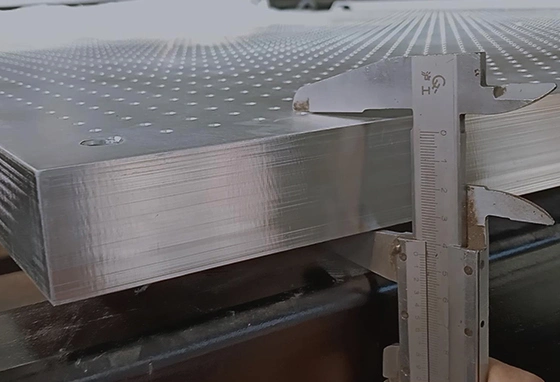

The worktable is a high precision and strength aluminum honeycomb vacuum absorption worktable. Cooperate with high power vacuum pump to fix the material.

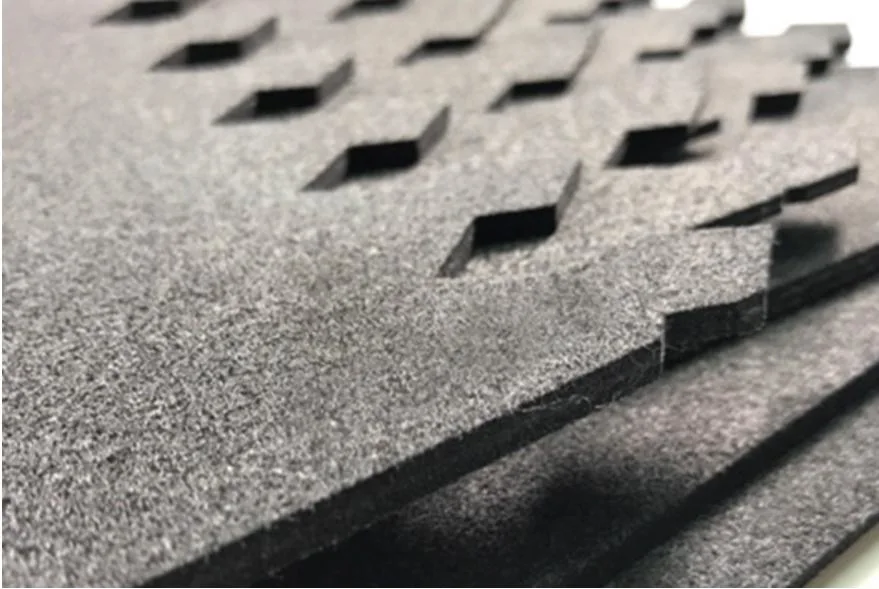

Imported Holland 4mm felt with built-in fiber tensile layer to protect the vacuum table and blades while the machine is working. Cutting-resistant, soft, won't scratch the product, non-slip, prevent the material from shifting during the cutting process.

Use top quality Japan Panasonic servo motors and drivers. Strong power, long life, and high precision.

A variety of tool combinations, equipped with intelligent tools interchange system, can cut different materials to achieve different tasks, and multiple tool heads can work individually or in concert. Powerful function, fast running speed, high processing accuracy, truly multi-purpose machine.

Safety protection device. Highly sensitive collision avoidance system and red light brake system. When the machine is cutting at high speed, it can effectively protect safety of the operator.

Taiwan PMI 20mm high precision linear guide, high positioning accuracy, high repeatability. Low friction resistance, high rigidity four-way load design, high speed and long time operation to maintain high precision

High power vacuum pump to fix material. The vacuum pump runs automatically when the machine is working.

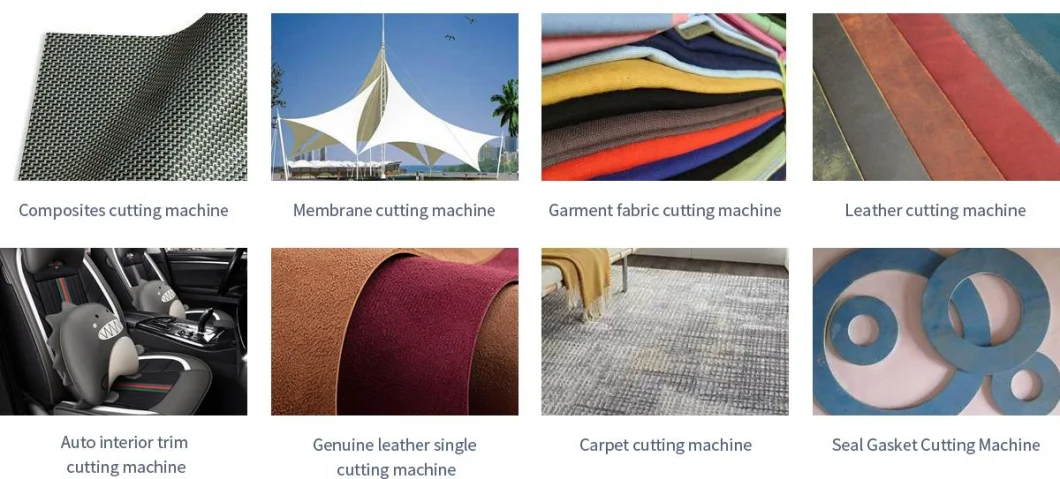

Applications:

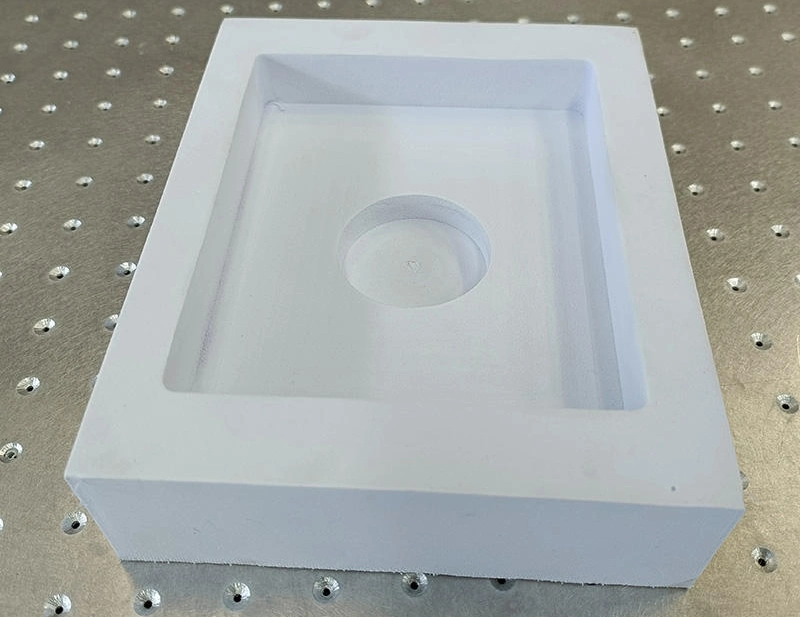

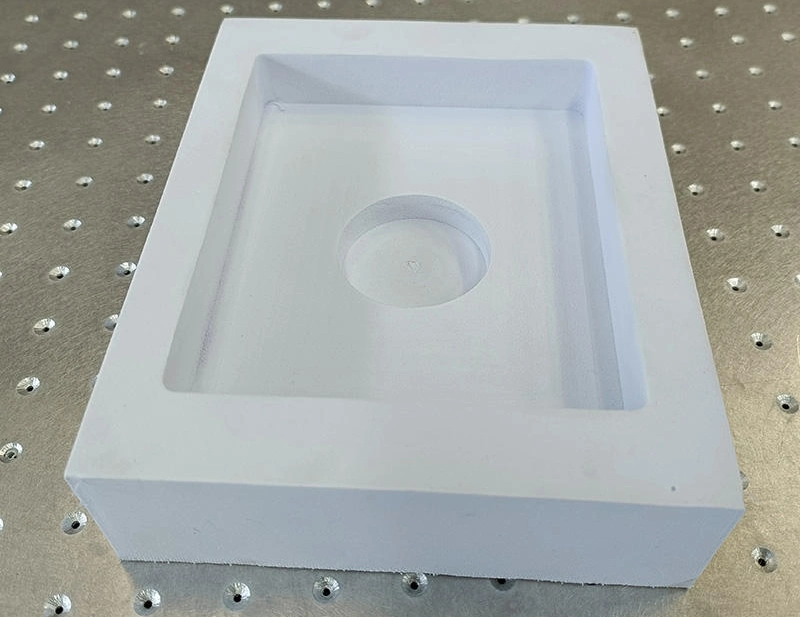

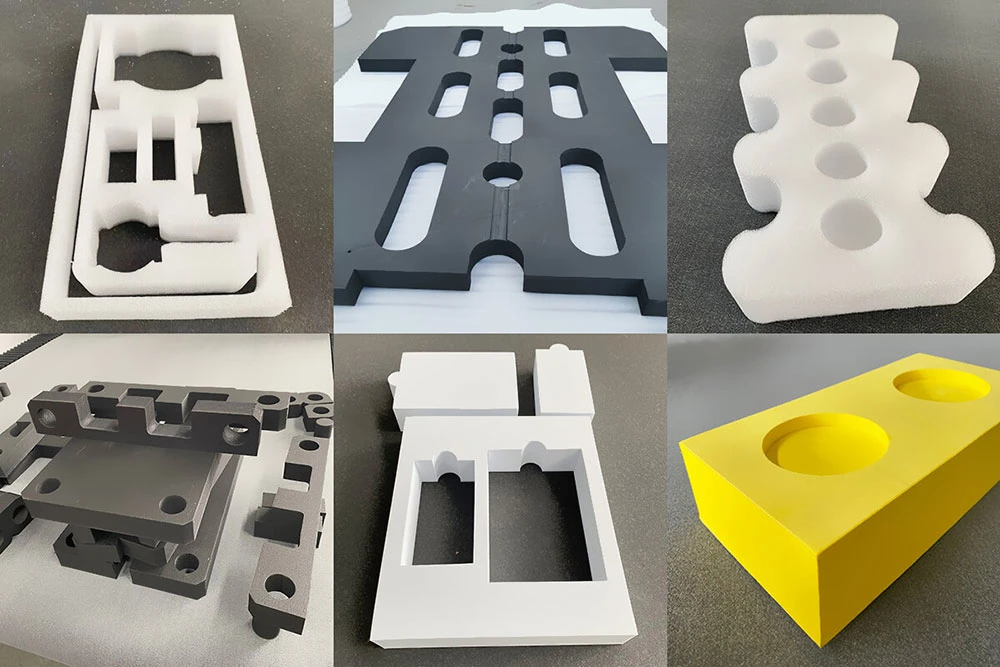

EVA is a shock-proof packaging material, which is often used to make packaging inserts. It not only has a good shock-proof effect, but also the product is not easy to be damaged by collision. At the same time, it can be used as an anti-static material in the electronics industry, which can play a very good anti-static effect.

So how to quickly and perfectly cut EVA foam for custom packaging inserts?

The traditional stamping production process is suitable for EVA foam boards with a thickness of less than 40MM. Although it is suitable for mass production of foam inserts, it requires a large number of molds and cannot be adapted to make multiple styles of customized foam inserts. In addition, the use of stamping process will cause the EVA foam edge to be easily deformed, resulting in uneven internal structure and appearance, and poor accuracy.

Compared with traditional die cutting and CO2 laser cutting, Rubycnc packaging industry proofing machine does not require die, saves time and labor, and has the advantages of accurate sample cutting, smooth edge, no sawtooth, no yellowing and coke, no powder dust, smoke, odor, etc. Safety and environmental protection, easy maintenance and low cost of use, greatly shorten the development cycle of user styles, and solve the problem of difficult production and processing of small batch orders. Users can also choose a large vision system, projector, multiple heads, double beams, lengthening and widening the working area of the cutting machine, etc. to meet different personalized production needs.

Advantages of cutting EVA foam inserts with a CNC oscillating knife cutter:

1) The CNC oscillating knife cutting machine does not need to make any molds, and can meet the shape and size customization of various packaging inserts;

2) Computer programming can cut any graphics, with high precision, flat die-cutting surface, and the entire product can be cut and formed at one time;

3) The overall appearance of the packaging box is flat and beautiful, and the delivery cycle is short, which enhances the competitiveness of the foam packaging insertion factory.

More Applications:

More Samples:

Cutting Tools:

Why Choose Us?

We provide customers with automated production equipment that replaces skilled workers and reduces labor costs.

We equip our machines with automated typesetting software that provides customers with an optimal layout plan, maximizes material utilization and avoids wasted material.

Our equipment is easy to operate. The digitalized processing transforms "old-fashioned" repetitive work (typesetting, changing size, etc.) into one operation, making it more "user-friendly," reducing employee turnover and its negative effects on production.Digital production enables a seamless cooperation between machine and man that has never before been possible.

The efficiency of our machines is unparalleled and the supply cycle is shortened, which makes our customers become the leaders once again in a highly competitive industry.