Basic Info.

Model NO.

DO-1625S

Application

Plastic, Fabric

Power Source

Electric

Layout

Horizontal

Working Size

1600X2500mm

Transmission

Helical Rack and Wheels

Drving System

Japan Panasonic Servo Motors+Precision Reducers

Transport Package

Wood

Specification

1625

Trademark

DEVEUP

Origin

Jinan China

HS Code

8441100000

Production Capacity

50 Sets Per Month

Product Description

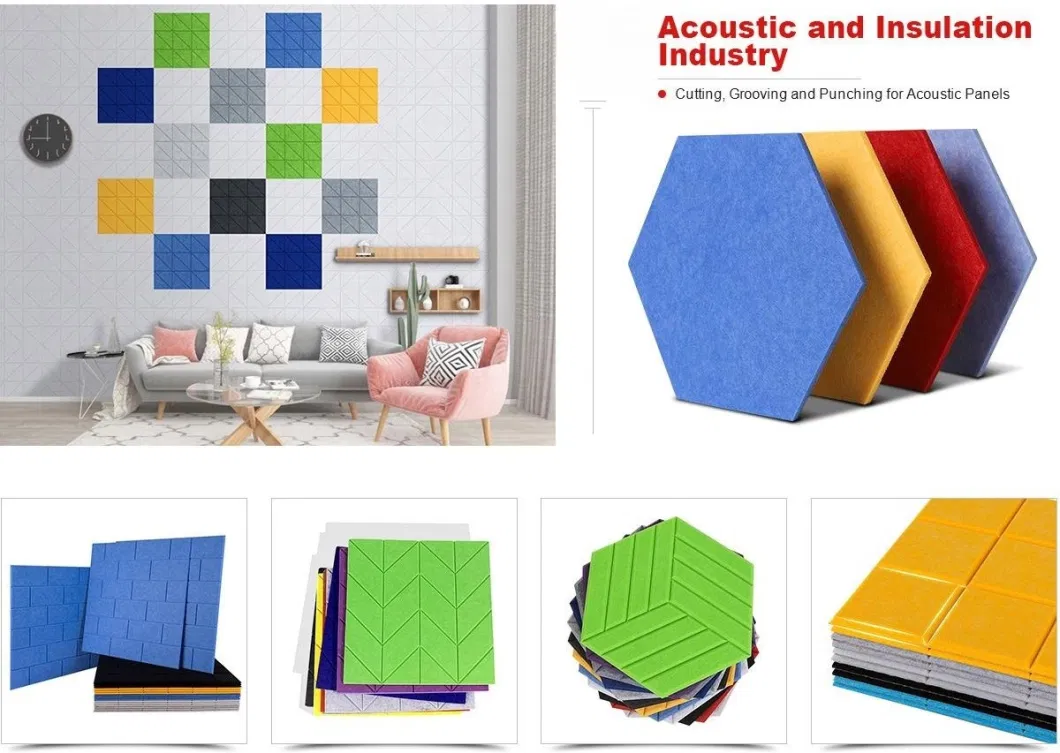

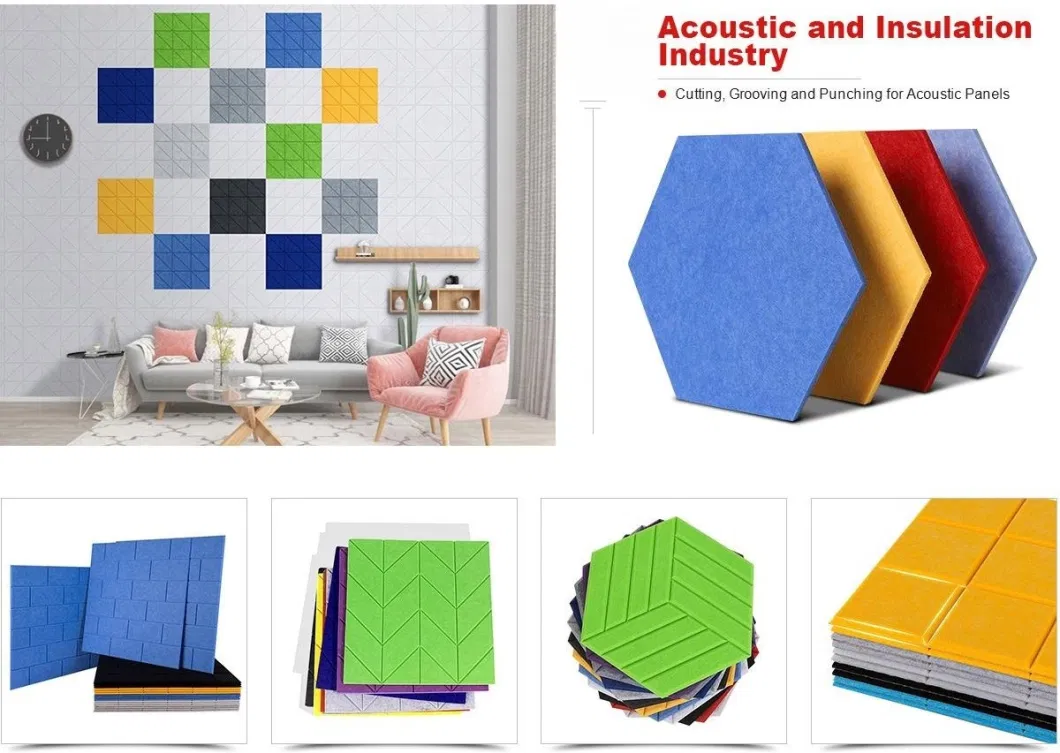

DEVEUP CNC knife cutter machine for rubber fiberglass rock wool aluminum silicate cotton phenolic foam insulation board polyester PET acoustic panel

What kind of insulation materials can the insulation foam cutting machine cut? It can cut rubber foam, fiberglass wool, rock wool, aluminum silicate wool, phenolic foam insulation board, polyester fiber acoustic board and other thermal insulation cotton materials and acoustic acoustic panels. Manual cutting is the traditional cutting method. What are the advantages of insulation cotton cutting machine over the traditional manual cutting?

1, some of the insulation cotton material will produce certain hazards to the human body, such as glass fiber cotton will affect the lungs and respiratory tract, and may cause contact dermatitis, manual cutting need to wear protective clothing. Insulation cotton cutting machine reduces the artificial contact with the material, reducing the harm to the human body.

2, the precision of manual cutting is relatively low, manual cutting when the sample on the material, and then use the wallpaper cutter to extend the sample cut, the cutting edge is not neat and easy to pull, affecting the installation of the aesthetics and precision. Insulation cotton cutting machine is CNC vibrating knife cutting machine, vibrating knife cutting machine using high-frequency vibration knife cutting insulation cotton, cutting high precision, and cut the edge of the clean neat and smooth.

3, manual cutting insulation cotton cost is higher, the efficiency is slower. Fiberglass cotton, for example, vibrating knife cutting machine can cut ten square a day, if the manual cutting ten square, need three people to work two days, insulation cotton cutting machine to improve processing efficiency and reduce labor costs.

4, insulation cotton cutting machine can be optional automatic feeding table, the machine can automatically pull the material forward, to achieve the continuous cutting of the coil.

5, DEVEUP cnc oscillating knife cutting machine utilizes vacuum adsorption to fix the material, vacuum adsorption automatic start and stop.

In addition to insulation wool and acoustic panel materials, DEVEUP intelligent vibrating knife cutting machine can also cut EVA foam, pearl cotton, polyurethane fiber cotton, packing carton, corrugated carton, honeycomb cardboard, hollow board, glass fiber, carbon fiber, aramid fiber, leather, fabric and other flexible materials with fast speed and easy operation without mold. Just import the CAD drawing into the machine cutting software, the software will automatically optimize the layout, one key cutting, save time and effort.

Specifications:

Why Choose Us?

We provide customers with automated production equipment to replace skilled workers and reduce labor costs.

Our cutting equipment is equipped with automatic layout software, which can provide customers with the best layout plan to maximize material utilization and avoid wasting materials.

Our oscillating cnc knife cutting machines are easy to operate. Digital processing transforms "old-fashioned" repetitive tasks (nesting, changing sizes, etc.) into an operation that is more "user-friendly" and reduces employee turnover and its negative impact on production.

Digital production enables a seamless collaboration between machines and people like never before.

The high efficiency of our machines and the shortening of lead times allow our customers to once again stand out from the fierce competition in their industry.

What kind of insulation materials can the insulation foam cutting machine cut? It can cut rubber foam, fiberglass wool, rock wool, aluminum silicate wool, phenolic foam insulation board, polyester fiber acoustic board and other thermal insulation cotton materials and acoustic acoustic panels. Manual cutting is the traditional cutting method. What are the advantages of insulation cotton cutting machine over the traditional manual cutting?

1, some of the insulation cotton material will produce certain hazards to the human body, such as glass fiber cotton will affect the lungs and respiratory tract, and may cause contact dermatitis, manual cutting need to wear protective clothing. Insulation cotton cutting machine reduces the artificial contact with the material, reducing the harm to the human body.

2, the precision of manual cutting is relatively low, manual cutting when the sample on the material, and then use the wallpaper cutter to extend the sample cut, the cutting edge is not neat and easy to pull, affecting the installation of the aesthetics and precision. Insulation cotton cutting machine is CNC vibrating knife cutting machine, vibrating knife cutting machine using high-frequency vibration knife cutting insulation cotton, cutting high precision, and cut the edge of the clean neat and smooth.

3, manual cutting insulation cotton cost is higher, the efficiency is slower. Fiberglass cotton, for example, vibrating knife cutting machine can cut ten square a day, if the manual cutting ten square, need three people to work two days, insulation cotton cutting machine to improve processing efficiency and reduce labor costs.

4, insulation cotton cutting machine can be optional automatic feeding table, the machine can automatically pull the material forward, to achieve the continuous cutting of the coil.

5, DEVEUP cnc oscillating knife cutting machine utilizes vacuum adsorption to fix the material, vacuum adsorption automatic start and stop.

In addition to insulation wool and acoustic panel materials, DEVEUP intelligent vibrating knife cutting machine can also cut EVA foam, pearl cotton, polyurethane fiber cotton, packing carton, corrugated carton, honeycomb cardboard, hollow board, glass fiber, carbon fiber, aramid fiber, leather, fabric and other flexible materials with fast speed and easy operation without mold. Just import the CAD drawing into the machine cutting software, the software will automatically optimize the layout, one key cutting, save time and effort.

Specifications:

| Parameters/Model | DO1625S |

| Working Size | 1600*2500mm |

| Cutting tools | Oscillating Tool + V-Cut Tool |

| Safety device | Physical anti-collision mechanism + infrared induction anti-collision to ensure production safety |

| Cutting thickness | ≤50mm (Other thickness can be customized according to the material) |

| Cutting speed | ≤1500mm/s(The actual speed depends on the material and cutting graphics) |

| Applicable materials | Rubber foam, fiberglass wool, rock wool, aluminum silicate cotton, phenolic foam insulation board, polyester fiber acoustic panels and other thermal insulation cotton materials and acoustic panels |

| Cutting precision | ± 0.1mm |

| Repeat accuracy | <= 0.05mm |

| Cutting circular diameter | >=3mm Diameter |

| Positioning way | Laser positioning also optional CCD camera positioning |

| Safety device | Infrared induction, safe and reliable |

| Material fixed way | Vacuum adsorption |

| Transport interface | Ethernet front-end ports |

| Compatible software format | AI software, AutoCAD, CorelDRAW, and all of the box type design software can output directly, without conversion, and with automatic optimization |

| Command system | AI, PLT, DXF, CDR and ETC |

| Operation panel | Multilingual LCD touch panel |

| Transmission system | High precision linear guide, meshing transmission gear and rack structure, screw, high performance servo motor and drive |

| Power supply voltage | Ac 220 v to 380 v + 10%, 50 hz. The machine power 9.5 kw. |

| Pump power | 9KW |

| Work environment | Temperature: - 10 ºC to 40 ºC, humidity: 20% ~ 80% RH |

Why Choose Us?

We provide customers with automated production equipment to replace skilled workers and reduce labor costs.

Our cutting equipment is equipped with automatic layout software, which can provide customers with the best layout plan to maximize material utilization and avoid wasting materials.

Our oscillating cnc knife cutting machines are easy to operate. Digital processing transforms "old-fashioned" repetitive tasks (nesting, changing sizes, etc.) into an operation that is more "user-friendly" and reduces employee turnover and its negative impact on production.

Digital production enables a seamless collaboration between machines and people like never before.

The high efficiency of our machines and the shortening of lead times allow our customers to once again stand out from the fierce competition in their industry.