- Overview

- Product Parameters

- Product Description

- Installation Instructions

- Packaging & Shipping

Basic Info.

Model NO.

OBX-C600

Voltage

220V

Customized

Customized

Capacity

6000PCS

Certificate

CE/ISO

Motors

Servo

PLC

Simens

Transport Package

Wooden Boxes

Specification

stainless steel 304 large capacity

Trademark

OBAKING/OBESINE

Origin

China

HS Code

8438800000

Production Capacity

3000pieces

Product Description

Alternative title: XXXXX

OBAKING FACTORY SUPPLIES ONE-STOP BAKERY EQUIPMENTS FOR CAKE PRODUCTION COMMERCIAL AND INDUSTRIAL

EGGS PROCEESING MACHINERY EQUIPMENTS

includes egg conveying ,egg automatic cleaning and egg detecting ,egg sterilizer , the whole equipment line solution and layout ,also we accept the customized projects .

OBAKING -Full automatic High speeds and large capacity egg cracking machine line

OBAKING egg cracker machine -OBX-350/600/800/1000 has sound models and functions, suitable for food factories of different scales and production needs.

This machine imitates the manual egg knocking action to realize the automatic separation of egg shell and egg liquid, and can be equipped with a filter to realize the separation of egg yolk and egg white. This machine has reasonable structure, sturdiness and durability, simple operation and convenient cleaning. The machine has stable performance, high production efficiency and good separation effect. It is widely used for making cakes, desserts, pies, pasta and other foods, and is suitable for large cake food processing plants.

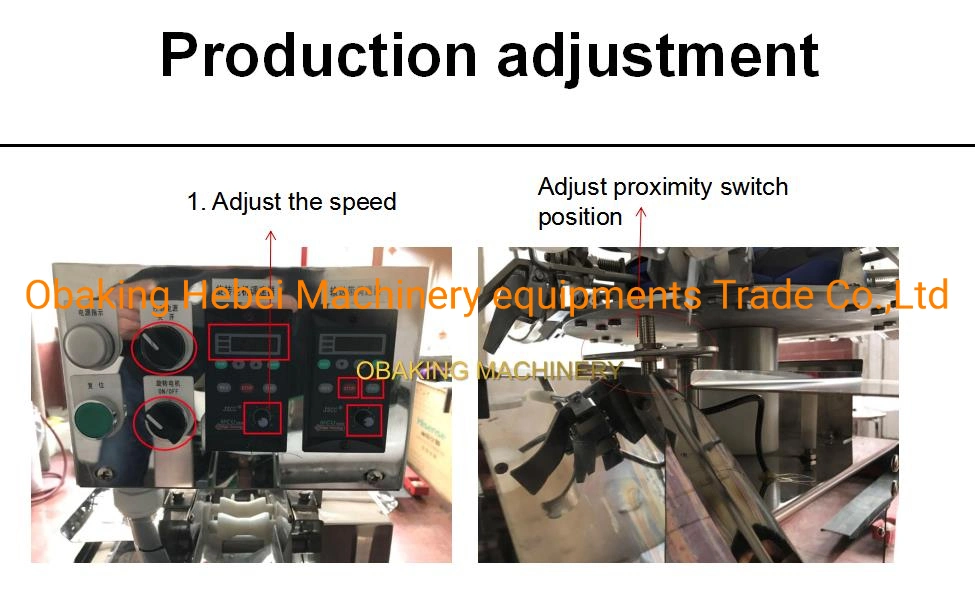

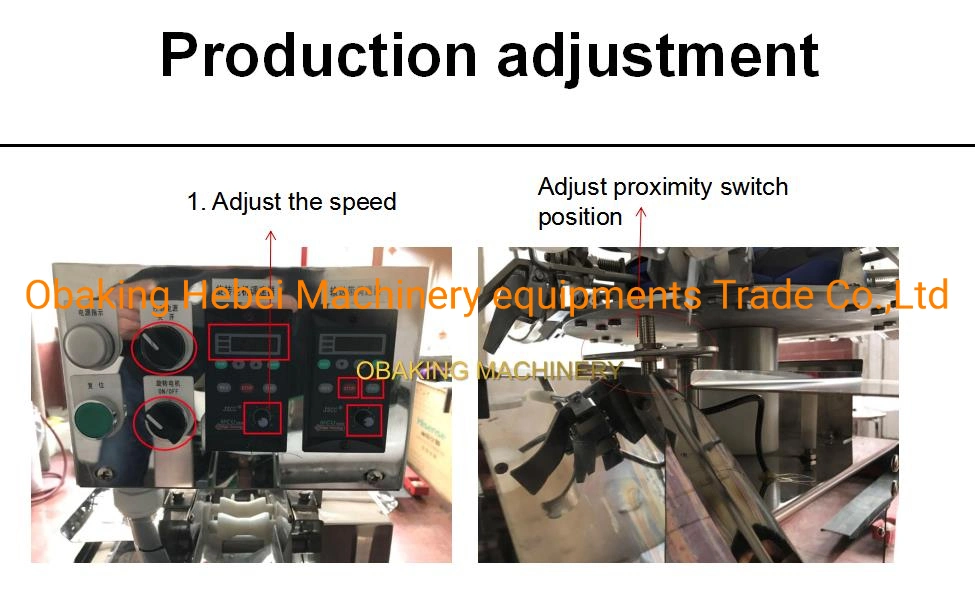

1. The whole machine adopts programmable controller or Siemens touch screen system to realize continuous operation of fully automatic links such as loading, picking, knocking, breaking, separating, throwing, etc., such as adding a filter to realize the separation of egg yolk and egg white ; Speed can be adjusted freely,

2. There is less residual liquid in the eggshell after treatment, avoiding artificial waste;

3. System integration, stable performance, simple maintenance

4. It can replace labor and reduce production costs; it has large production capacity and high efficiency.

5. Widely used in various foods sweets and snacks industries etc ,food processing enterprises. It has created favorable conditions for hygiene and health.

Models and technical parameters

OBAKING INDUSTRIAL CAKE PRODUCTION LINE WITH INLINE EQUIPMENTS

OBAKING INDUSTRIAL CAKE PRODUCTION LINE WITH INLINE EQUIPMENTS

Step 1: Turn on the display screen, start, automatically open the lid, feed, time setting, aerated feed, and auto discharge are all automated systems, no other operations are required.

Step 2: The storage barrel should be kept between 6°C~16°C to prevent the weather from affecting the cake batter organization (optional according to the factory workshop environment), and then pump the material in the storage barrel to the blower head to completely blow . This can be adjusted according to customer needs. The fan ratio can be adjusted according to customer needs! In the middle, it can save personnel handling and unloading, and can continuously convey ingredients.

For example, light oil, a small specific gravity inflatable egg beater spends about 3 minutes, the beat rate is (about 0.23), the beat rate is the lowest (0.18-0.20), the inflatable egg beater can continuously feed, store, and feed continuously. The personnel only need ingredients and are optimistic about the equipment and mixing level. Directly operate the touch screen to complete. It can save a lot of labor costs and greatly improve the efficiency of the enterprise.

OBAKING FACTORY SUPPLIES ONE-STOP BAKERY EQUIPMENTS FOR CAKE PRODUCTION COMMERCIAL AND INDUSTRIAL

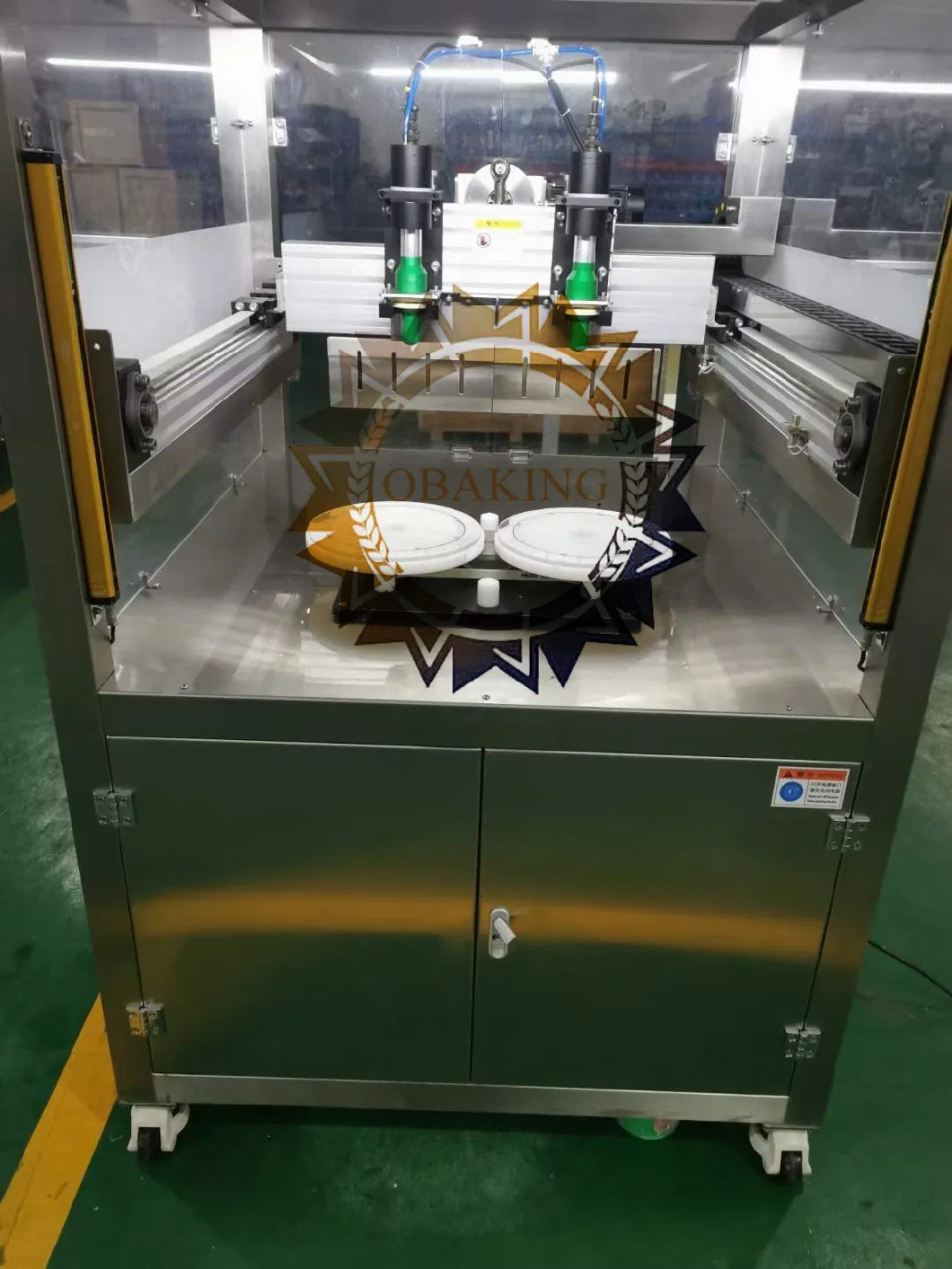

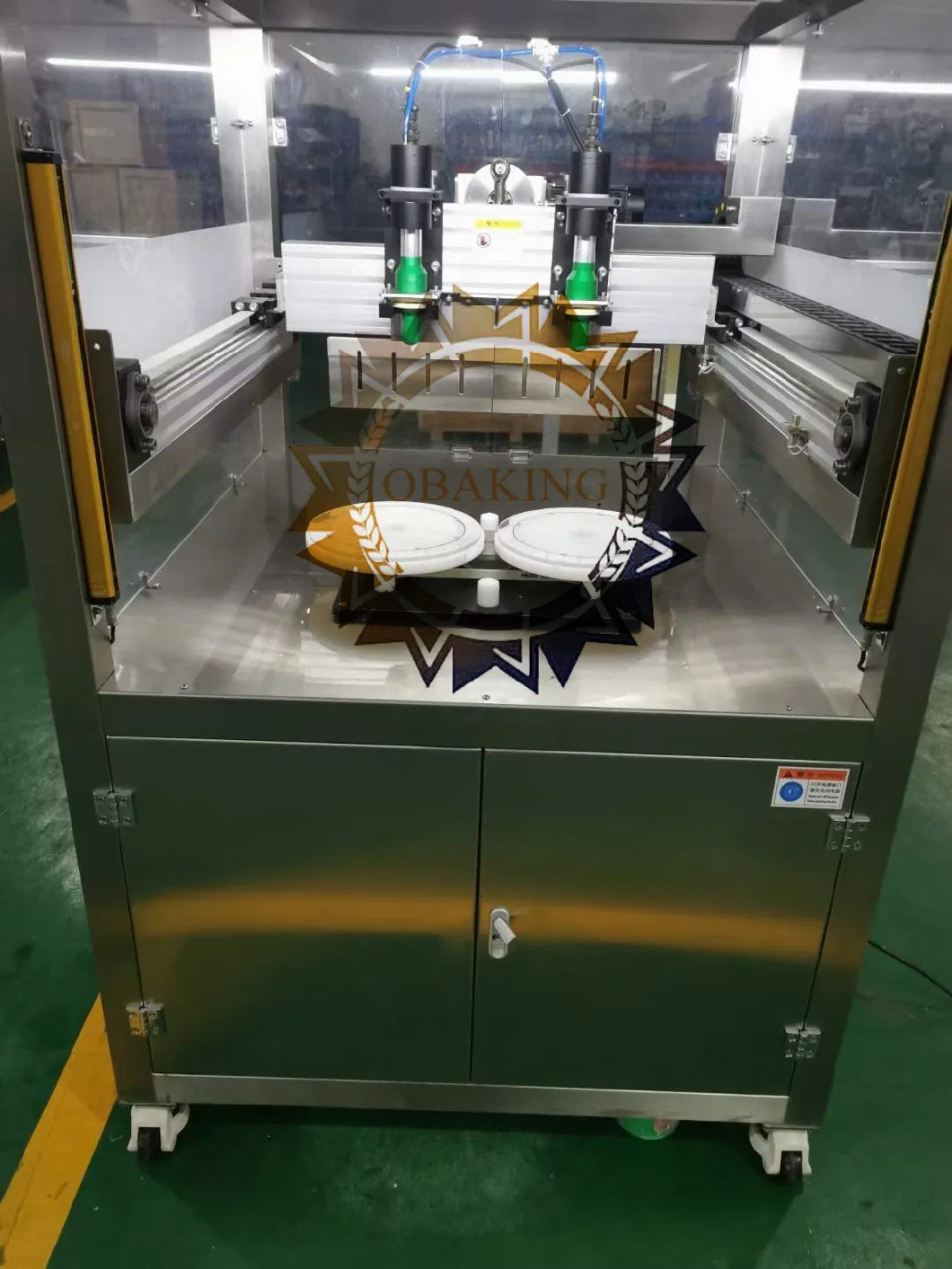

OBAKING -The ultrasonic food cutting equipment is composed of an ultrasonic transducer, a housing, a horn, a titanium alloy knife and a numerical control drive power supply. Ultrasonic food cutting machine is an innovation in food processing. The ultrasonic food cutter vibrates at a high frequency of 40kHz or 20kHz. This high frequency vibration reduces the frictional resistance on the cutting surface. This low friction enables the cutting knife to cut the food smoothly, so that the cutting surface of the food is clean, beautiful, and does not deform. In addition, ultrasonic cutting reduces food fragments during the cutting process. This reduces more downtime to clean up your production system. Ultrasonic food knives can also be easily installed in your current production system to help you better finishing,

Usage range:

CAKE Ultrasonic cutter machine

(1) Cake cutting/cheese cutting

(2) Bread and biscuit cutting (with the characteristics of fine cut, no crumb, no slag, and no deformation.)

(3) Sandwich cutting (solve the problems of deformation, unevenness, leakage of food materials, and unsightly cut surface during the cutting process of sandwich products.)

4) Candy cutting (Solved the problems of sticking knives, melting of candy, and severe tool wear during the cutting process.)

ADVANTAGE

Usage range:

CAKE Ultrasonic cutter machine

(1) Cake cutting/cheese cutting

(2) Bread and biscuit cutting (with the characteristics of fine cut, no crumb, no slag, and no deformation.)

(3) Sandwich cutting (solve the problems of deformation, unevenness, leakage of food materials, and unsightly cut surface during the cutting process of sandwich products.)

4) Candy cutting (Solved the problems of sticking knives, melting of candy, and severe tool wear during the cutting process.)

ADVANTAGE

- Ultrasonic cutting machine to automatically cut slab cakes,biscuit rolls,slab cakes in

trays,cheese,dough,fruit bars,round cakes and similar products.

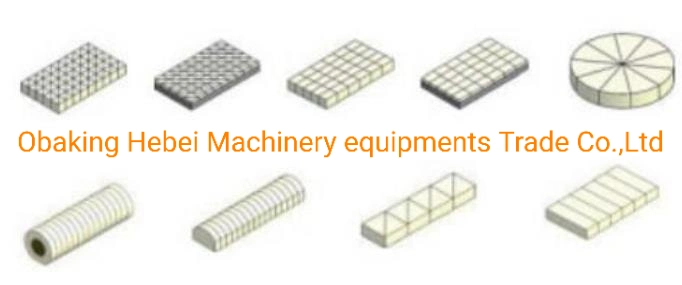

- Allow to set multiple cutting modes,including slice,or square, or triangular ,or circle

type.

- Easy to operate,labor saving.

- Open machine design for easy.

- PLC control system.

- Strong stainless steel 304 machine frame for a rough bakery working day.

Multi-layer product cutting, can keep the color between layers

Advantages of ultrasonic cutting: fine cut, no chips, no sticking to the knife

Multi-function type, composed of multiple sets of cutting knives, suitable for product assembly line use.

A wide range of cutting objects, both frozen products and cream-containing products can be adapted

The cutting model of products can be customized according to the needs of customers

Feature

Fast and precise because of unique servo technology.

Advanced software to set product parameters using icons on the touch screen.

Set your own cutting pattern (also on the touch screen).

A high quality safety system prevents access of the cutting area during operation.

For rectangular,triangular and circle products.

Movable on 4 swivel wheels.

For your convenience available in English language

Advantages

Advantages

Multi-layer product cutting, can keep the color between layers

Advantages of ultrasonic cutting: fine cut, no chips, no sticking to the knife

Multi-function type, composed of multiple sets of cutting knives, suitable for product assembly line use.

A wide range of cutting objects, both frozen products and cream-containing products can be adapted

The cutting model of products can be customized according to the needs of customers

Technical Parameter

| Model | Specifications | cutting shapes |

| Voltage | 220V/60HZ 50HZ | Round/ square/ rectangular,triangular and circle products. |

| Power | 3.5 | |

| Size | 1800*1050*1750MM | |

| Weight | 600KGS | |

| length of blade | 1*300/1*150 | |

| size | 4 inch-18 inch |

Automatic egg processing equipments line

EGGS PROCEESING MACHINERY EQUIPMENTS

includes egg conveying ,egg automatic cleaning and egg detecting ,egg sterilizer , the whole equipment line solution and layout ,also we accept the customized projects .

OBAKING -Full automatic High speeds and large capacity egg cracking machine line

OBAKING egg cracker machine -OBX-350/600/800/1000 has sound models and functions, suitable for food factories of different scales and production needs.

This machine imitates the manual egg knocking action to realize the automatic separation of egg shell and egg liquid, and can be equipped with a filter to realize the separation of egg yolk and egg white. This machine has reasonable structure, sturdiness and durability, simple operation and convenient cleaning. The machine has stable performance, high production efficiency and good separation effect. It is widely used for making cakes, desserts, pies, pasta and other foods, and is suitable for large cake food processing plants.

1. The whole machine adopts programmable controller or Siemens touch screen system to realize continuous operation of fully automatic links such as loading, picking, knocking, breaking, separating, throwing, etc., such as adding a filter to realize the separation of egg yolk and egg white ; Speed can be adjusted freely,

2. There is less residual liquid in the eggshell after treatment, avoiding artificial waste;

3. System integration, stable performance, simple maintenance

4. It can replace labor and reduce production costs; it has large production capacity and high efficiency.

5. Widely used in various foods sweets and snacks industries etc ,food processing enterprises. It has created favorable conditions for hygiene and health.

Models and technical parameters

| OBX-5H | OBX-8H | 12H |

| 110V/220V/0.6KW 1PH | 110V/220V/0.8KW 1PH | 110V/220V1KW 1PH |

| Size 1250*800*1200mm | Size 1250*800*1200mm | Size 1250*800*1200mm |

| capacity 2800/hour | capacity 3600pieces/hour | 6000pieces/hour |

| 150kgs | 220kgs | 250kgs |

OBAKING INDUSTRIAL CAKE PRODUCTION LINE WITH INLINE EQUIPMENTS

OBAKING INDUSTRIAL CAKE PRODUCTION LINE WITH INLINE EQUIPMENTS

The operation process

Step 1: Turn on the display screen, start, automatically open the lid, feed, time setting, aerated feed, and auto discharge are all automated systems, no other operations are required.

Step 2: The storage barrel should be kept between 6°C~16°C to prevent the weather from affecting the cake batter organization (optional according to the factory workshop environment), and then pump the material in the storage barrel to the blower head to completely blow . This can be adjusted according to customer needs. The fan ratio can be adjusted according to customer needs! In the middle, it can save personnel handling and unloading, and can continuously convey ingredients.

For example, light oil, a small specific gravity inflatable egg beater spends about 3 minutes, the beat rate is (about 0.23), the beat rate is the lowest (0.18-0.20), the inflatable egg beater can continuously feed, store, and feed continuously. The personnel only need ingredients and are optimistic about the equipment and mixing level. Directly operate the touch screen to complete. It can save a lot of labor costs and greatly improve the efficiency of the enterprise.