Basic Info.

Transport Package

Standard Export Packing

Specification

Electric

Trademark

Midtech

Origin

China

HS Code

84778000

Production Capacity

10 Sets/ One Year

Product Description

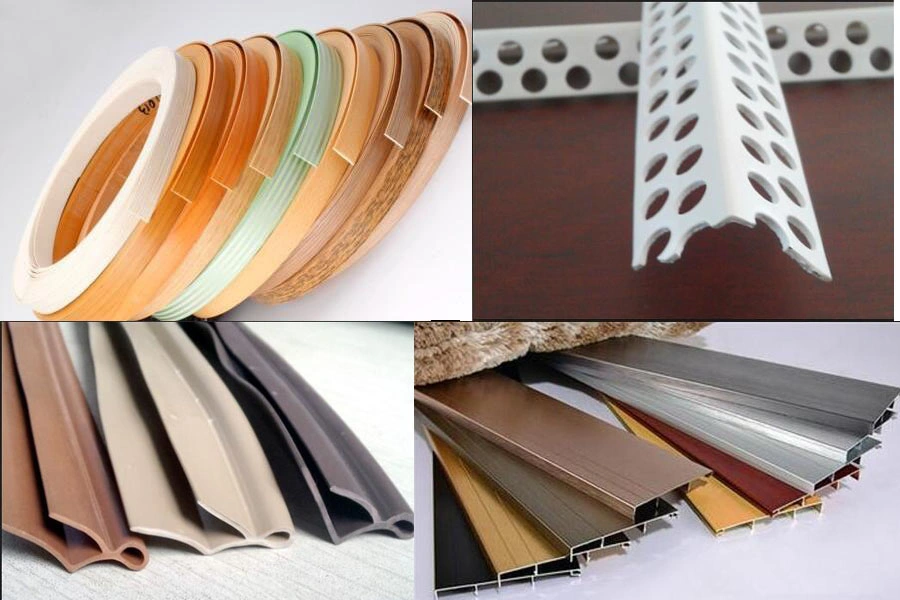

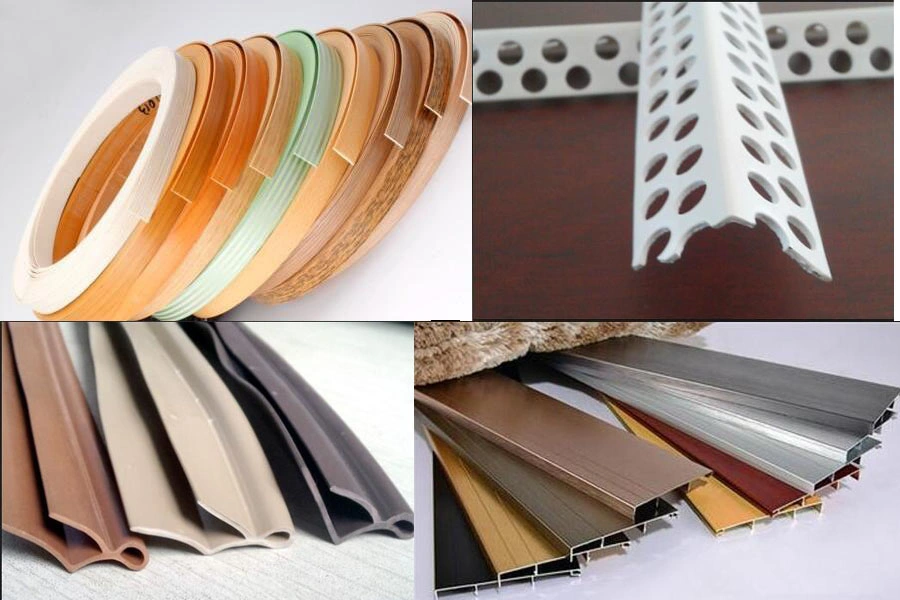

Plastic PVC corner bend/Edge banding/band sheet profile making machine

Through market combination and our technology innovation, Midtech pleased to provide

- High capacity ( Max 6 cavities )

- Low material cost (Cheap formulation)

- H igh lineal speed ( 6-8 m/min),

- Colorful surface (Hot stamp or mix color master batch)

Plastic Extruder and PVC corner bend/Edge banding/band profile making machine

Process Flows:

Plastic(PVC) + additives

high speed heating mixer --- PVC extruder-- Die --- Calibration table---haul off--- pneumatic cutter --- stacker

Technical Parameter

Workshop

Product package

Choose us

Through market combination and our technology innovation, Midtech pleased to provide

- High capacity ( Max 6 cavities )

- Low material cost (Cheap formulation)

- H igh lineal speed ( 6-8 m/min),

- Colorful surface (Hot stamp or mix color master batch)

Plastic Extruder and PVC corner bend/Edge banding/band profile making machine

Process Flows:

Plastic(PVC) + additives

high speed heating mixer --- PVC extruder-- Die --- Calibration table---haul off--- pneumatic cutter --- stacker

Technical Parameter

| Feeder | • To feed material into extruder; |

| Extruder | •World famous brand electrical component: Siemens,Schneider, ABB etc; • High torque gearbox with adopts NSK/SKF bearing; • Siemens/WEG original motor achieved global after service; • Bimetallic screw and barrel; • Intelligent PLC controlling system with human-friendly interface. |

| Die head | • 3Cr13/3Cr17 material • Straight extrusion sheet die |

| Calibration table | • Calibration mould • Length: 6000mm |

| Haul off | • Upper/lower caterpillar driven separately and speed control by inverter |

| Cutter | • Pneumatic cutter |

| Stacker | • Stainless steel304 as touching material • Discharge driving by air cylinder |

| Hot stamp machine | • Decorative pattern and different color |

Product package

Choose us