Basic Info.

Model NO.

1800mm

Structure

Horizontal

Volage

220--660V

Transport Package

Standard Wooden Case

Specification

Customer customization

Trademark

ZhiHongDa

Origin

China

HS Code

8477800000

Production Capacity

1000sets/Year

Product Description

Nonwoven Fabric Slitter Rewinder Machine

Name: Slitter Rewinder Machine with photoelectric induction correction function

Model: 1800mm

Descriptions:

Nonwoven Fabric, Melt-blown Fabric Slitter Rewinder Machine with touch screen is developed model for high speed production of bundle stretch wrap,banding wrap roll from the jumbo roll to small roll.

Machine is with the special features for rapid changing of rewinding shaft,it can save the shaft changing time to improve the production speed.

The Slitting Rewinder Machine machine operation is very simple via input the data in the touch screen only.

The control system is by PLC hub and touch screen for user friendly with world top brand premium quality to ensure heavy duty production endurable.

Machine is ideal to slit the PVC wire protection wrap film too,and PE food stretch wrap,PVC cling film etc.

Adapted materials:

Bubble film, PVC plastic film, PET film, PE heat shrinkable film, reflective film, EVA foam, leather, pearl cotton, bubble pad, Non-woven fabric, Melt-blown Fabric,insulating paper, adhesive paper, bronzing paper, copper foil aluminum foil, etc.

Features:

1. Simple operation and complete functions

2. The edge is sharp and wear-resistant

3. Rewinding width and length can be adjusted arbitrarily

4. Feeding rack with air expansion shaft, effectively prevent the inertia of coiling material

5. With photoelectric induction correction function, prevent material deviation

6. Magnetic particle clutch controller is used for unwinding and rewinding

Technical parameters:

Products show:

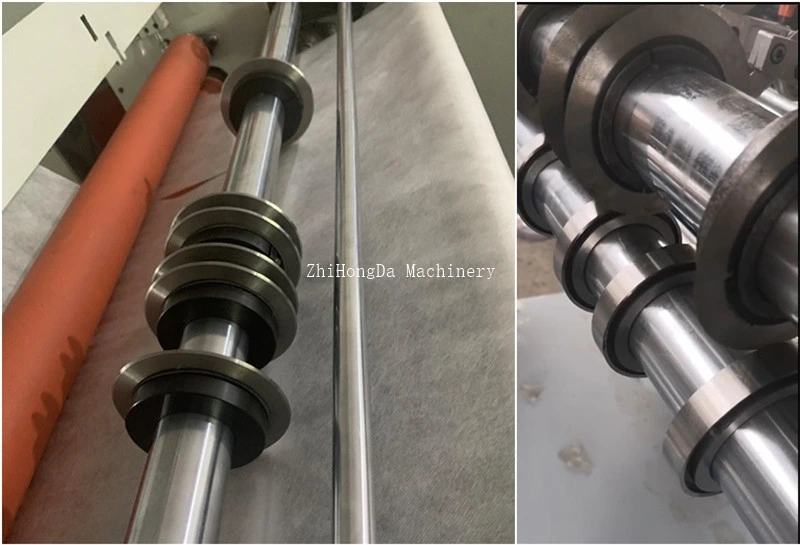

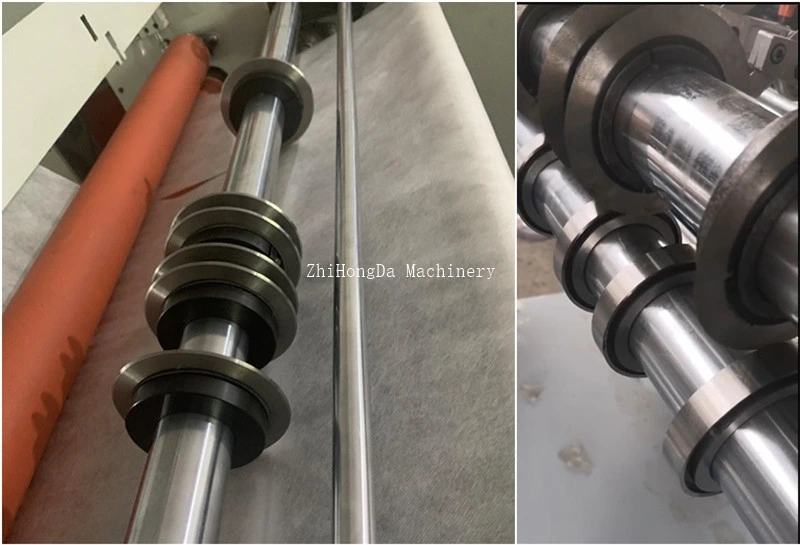

High quality tool material, reasonable upper and lower tool structure, high cutting precision

High quality tool material, reasonable upper and lower tool structure, high cutting precision

Machine test before delivery, perfect cutting and rewinding

Packing and Delivery

We offer below business term:

We offer below business term:

FAQ:

1.Q:How about your packing and shipment?

A:Products would be covered with pe film then put them into the standard wooden case, By Sea or by Air are available.

2.Q:What's the Payment method?

A:40% by T/T in advance, 60% balance by T/T paid off before shipment.

3.Q: Where is your factory ?

A: Our factory located in Qingdao City, Shandong, China.welcome you to visit our factory.

It takes about 1.5 hours driving from Qingdao air port.

4.Q:What's the warranty time?

A: Our warranty time is 12 months after the machine has been arrived at buyer's factory, during guarantee period, the cost of any spare parts or new accessory should be borne by the seller;Beyond the warranty period we only charged for the cost of spare part.

Name: Slitter Rewinder Machine with photoelectric induction correction function

Model: 1800mm

Descriptions:

Nonwoven Fabric, Melt-blown Fabric Slitter Rewinder Machine with touch screen is developed model for high speed production of bundle stretch wrap,banding wrap roll from the jumbo roll to small roll.

Machine is with the special features for rapid changing of rewinding shaft,it can save the shaft changing time to improve the production speed.

The Slitting Rewinder Machine machine operation is very simple via input the data in the touch screen only.

The control system is by PLC hub and touch screen for user friendly with world top brand premium quality to ensure heavy duty production endurable.

Machine is ideal to slit the PVC wire protection wrap film too,and PE food stretch wrap,PVC cling film etc.

Adapted materials:

Bubble film, PVC plastic film, PET film, PE heat shrinkable film, reflective film, EVA foam, leather, pearl cotton, bubble pad, Non-woven fabric, Melt-blown Fabric,insulating paper, adhesive paper, bronzing paper, copper foil aluminum foil, etc.

Features:

1. Simple operation and complete functions

2. The edge is sharp and wear-resistant

3. Rewinding width and length can be adjusted arbitrarily

4. Feeding rack with air expansion shaft, effectively prevent the inertia of coiling material

5. With photoelectric induction correction function, prevent material deviation

6. Magnetic particle clutch controller is used for unwinding and rewinding

Technical parameters:

| Model | 1800 |

| Max.slitting width | 1800mm |

| Max. unwinding diameter | 1000mm |

| Max. rewinding diameter/roll | 1000mm |

| Unwinding deviation correction | ≤0.5mm |

| Min.slitting width | 20mm |

| Slitting accuracy | ±0.1mm |

| Slitting speed | 5-80m/min |

| Slitting thickness | 15-400g/m2 |

| Slitting material | PVC/PE/Leather/Nonwoven Fabric/Meltblown Cloth/ plastic film etc |

| Rewind motor power | 3.0KW |

| Main motor power | 2.2KW |

| Winding and unwinding air expansion shaft | Standard diameter 74mm(can be customized) |

Products show:

High quality tool material, reasonable upper and lower tool structure, high cutting precision

High quality tool material, reasonable upper and lower tool structure, high cutting precision

Machine test before delivery, perfect cutting and rewinding

Packing and Delivery

We offer below business term:

We offer below business term: Accepted delivery terms | FOB, CFR, CIF, EXW |

Accepted payment currency | USD, EUR,CNY |

Accepted payment type | T/T, L/C |

Nearest port | Qingdao, Shanghai, Dalian, Tianjin,Ningbo etc. |

FAQ:

1.Q:How about your packing and shipment?

A:Products would be covered with pe film then put them into the standard wooden case, By Sea or by Air are available.

2.Q:What's the Payment method?

A:40% by T/T in advance, 60% balance by T/T paid off before shipment.

3.Q: Where is your factory ?

A: Our factory located in Qingdao City, Shandong, China.welcome you to visit our factory.

It takes about 1.5 hours driving from Qingdao air port.

4.Q:What's the warranty time?

A: Our warranty time is 12 months after the machine has been arrived at buyer's factory, during guarantee period, the cost of any spare parts or new accessory should be borne by the seller;Beyond the warranty period we only charged for the cost of spare part.