Basic Info.

Model NO.

GY-QZ001

Material

Stainless Steel

Capacity

101-200L

Structure

Vertical

Pressure

Bath Soap

Agitator Model

Ribbon Agitator

Tower Reactor Type

Plate Tower Reactor

Heating

Electric Heating

Automatic Grade

Automatic

Condition

New

Working

Rolling and Cutting

Stirring Type

Rolling and Cutting

Application

Solid Bar

Application Area

Chemical

Layout Type

Horizontal

Mixing Drum Shape

Disc

Additional Capabilities

Soap Stamping and Cutting Machine

Operating Type

Continuous Operating

Transport Package

Wooden Case

Specification

900*600*1200 mm

Trademark

SN

Origin

Guangdong, China

HS Code

8479899990

Production Capacity

100 Set/Month

Packaging & Delivery

Package Size

1200.00cm * 600.00cm * 900.00cm

Package Gross Weight

150.000kg

Product Description

Automatic Soap Cutting Machine

Machine description

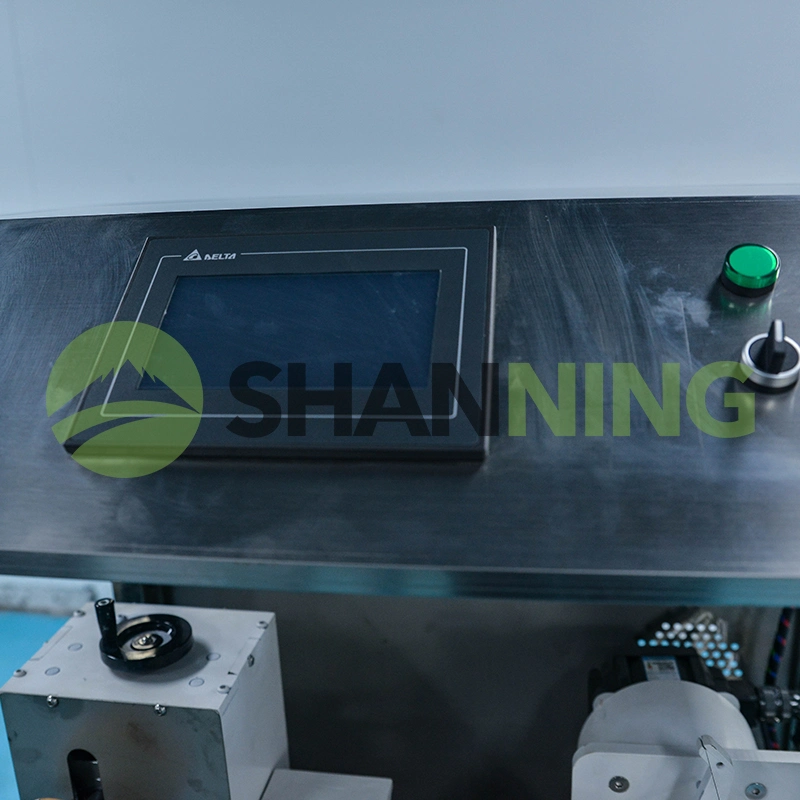

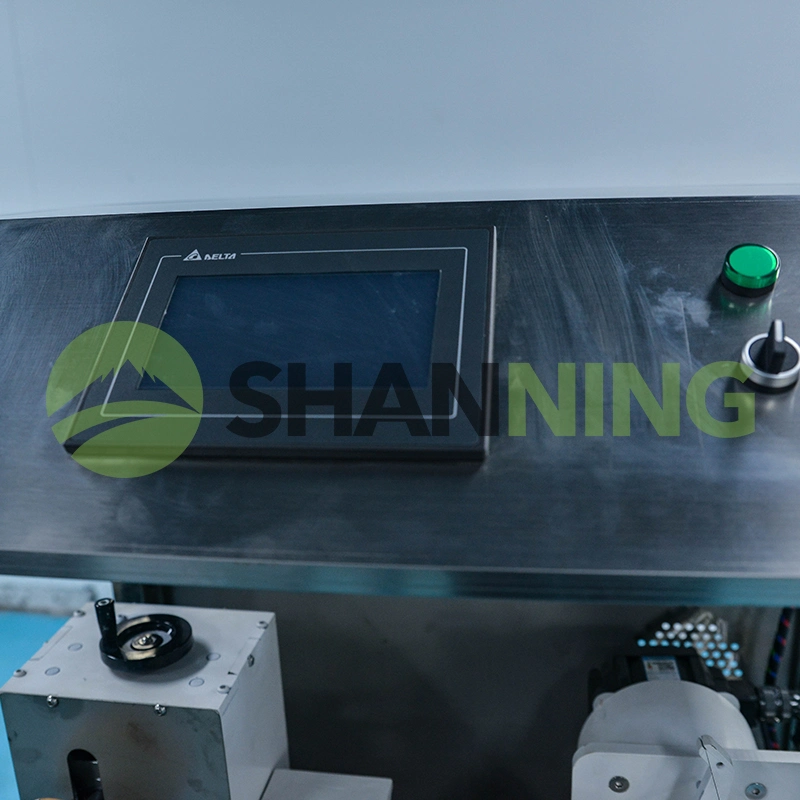

The electronic soap cutting machine is an intelligent roll printing and cutting product that continuously rolls and cuts soap bars extruded from the vacuum bar extruder. Its working principle is to use the soap bar extruded from the bar extruder to push the rolling wheel to rotate. According to the designed electronic cursor tracking system, the rotation of the rolling wheel is detected and the signal is transmitted to the servo motor control system to control the servo motor to drive the cutting wheel. The block wheel rotates to achieve soap cutting of any size and length. It is mainly used for roll printing and cutting soap and laundry soap with high speed and high precision. The control system composed of PLC, touch screen, servo, photoelectric encoder and conjugate cam linkage from world-renowned brands is used to ensure the high precision and reliability of the machine.

This equipment can perform roll printing on two or four sides of soap and transparent soap at the same time to meet special needs. at the same time, for large-capacity production lines, we are also able to perform two-channel simultaneous roll printing and cutting.

Machine Features

1. The roller printing wheel of the equipment relies on the soap bars extruded from the vacuum bar extruder to drive the rotation of the roller printing wheel. The two rollers are driven by bevel gears. They are light in weight and have good shock absorption and lubrication performance, ensuring that the upper and lower rollers The roller printing wheel rotates synchronously, and the printed fonts or patterns are aligned up and down, and the fonts are clear;

2. The roller printing wheel can be designed with a variety of fonts and patterns according to the different needs of customers, and can accurately produce soaps of various specifications and weights;

3. Adopt an electronic cursor tracking system and use photoelectric sensors to obtain operation signals. The processor used can switch the cutting length of the soap at will according to the customer's needs. At the same time, the cutting point of the cutting wheel can be adjusted to ensure that the cut surface of the soap is vertical and Beautiful.

Machine working principle

For soap production lines, the soap body coming out of the bar extruder is cut into long strips by this cutting machine and then input to the downstream printer. For laundry soap, this cutting machine can install a full set of roller printing devices at the front end of the equipment to realize roller printing and cutting at the same time. It has two functions and directly produces finished soap for downstream packaging.

Machine advantages

1. Touch screen control, soap bar length and cutter speed can be flexibly set, cutting is accurate, and operation is simple and convenient.

2. The roller printing mold is made of alloy copper and can be used for double-sided roller printing and four-sided roller printing.

3. The cutter is made of stainless steel, and the speed measuring wheel and guide wheel are made of rubber to protect the soap bar from scratches.

4. This equipment can be customized with dual outlet soap bars and used for soap bar cutting or soap block printing in large-volume production lines.

Machine description

The electronic soap cutting machine is an intelligent roll printing and cutting product that continuously rolls and cuts soap bars extruded from the vacuum bar extruder. Its working principle is to use the soap bar extruded from the bar extruder to push the rolling wheel to rotate. According to the designed electronic cursor tracking system, the rotation of the rolling wheel is detected and the signal is transmitted to the servo motor control system to control the servo motor to drive the cutting wheel. The block wheel rotates to achieve soap cutting of any size and length. It is mainly used for roll printing and cutting soap and laundry soap with high speed and high precision. The control system composed of PLC, touch screen, servo, photoelectric encoder and conjugate cam linkage from world-renowned brands is used to ensure the high precision and reliability of the machine.

This equipment can perform roll printing on two or four sides of soap and transparent soap at the same time to meet special needs. at the same time, for large-capacity production lines, we are also able to perform two-channel simultaneous roll printing and cutting.

Machine Features

1. The roller printing wheel of the equipment relies on the soap bars extruded from the vacuum bar extruder to drive the rotation of the roller printing wheel. The two rollers are driven by bevel gears. They are light in weight and have good shock absorption and lubrication performance, ensuring that the upper and lower rollers The roller printing wheel rotates synchronously, and the printed fonts or patterns are aligned up and down, and the fonts are clear;

2. The roller printing wheel can be designed with a variety of fonts and patterns according to the different needs of customers, and can accurately produce soaps of various specifications and weights;

3. Adopt an electronic cursor tracking system and use photoelectric sensors to obtain operation signals. The processor used can switch the cutting length of the soap at will according to the customer's needs. At the same time, the cutting point of the cutting wheel can be adjusted to ensure that the cut surface of the soap is vertical and Beautiful.

Machine working principle

For soap production lines, the soap body coming out of the bar extruder is cut into long strips by this cutting machine and then input to the downstream printer. For laundry soap, this cutting machine can install a full set of roller printing devices at the front end of the equipment to realize roller printing and cutting at the same time. It has two functions and directly produces finished soap for downstream packaging.

Machine advantages

1. Touch screen control, soap bar length and cutter speed can be flexibly set, cutting is accurate, and operation is simple and convenient.

2. The roller printing mold is made of alloy copper and can be used for double-sided roller printing and four-sided roller printing.

3. The cutter is made of stainless steel, and the speed measuring wheel and guide wheel are made of rubber to protect the soap bar from scratches.

4. This equipment can be customized with dual outlet soap bars and used for soap bar cutting or soap block printing in large-volume production lines.

Machine technical parameter

| Model | GY-QZ004 | |

| Material | 304 stainless steel 45# mold steel | |

| Cutting Speed | Cutting speed is determined by the single screw plodder | |

| Soap Cutting Size | According to customers' requirements | |

| Capacity | 0-200pcs/min | |

| Voltage | single phase,220v,50hz | |

| Power | 1.3 kw | |

| Machine size | 90*52*150CM | |

| Weight | 110kg |

Machine detail photos

Machine Application Field

Machine Application Field

This type of solid bar soap screw plodder machine mainly suitable for products such as round, strip, square and so on, daily necessities, chemical, medicine, hardware,food and other solid products.

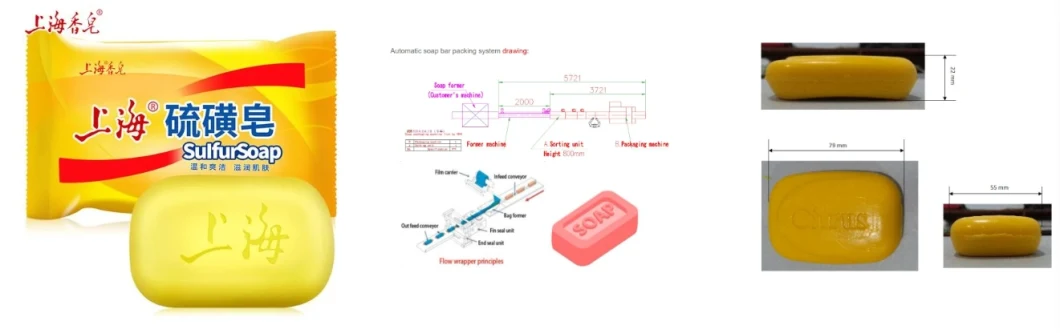

Finished packaging sample photos

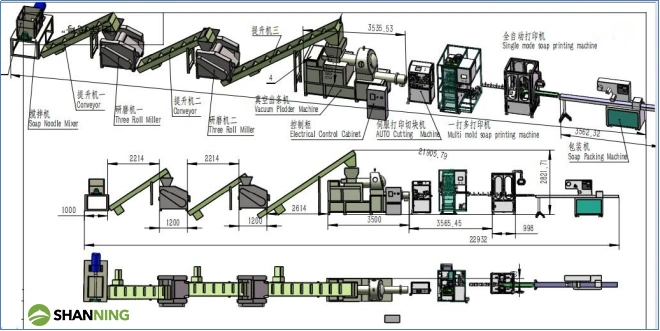

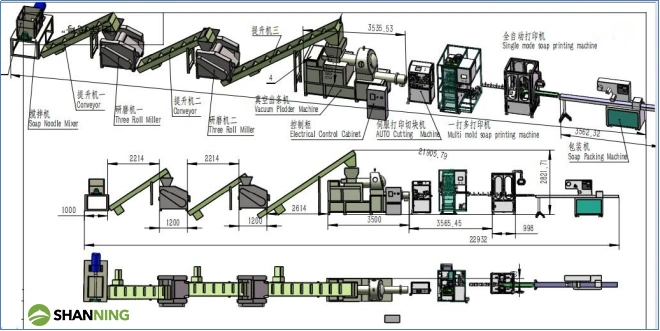

Soap production line

Soap production line use soap noodle to produce toilet soap bath soap hotel soap multi-pose soap. use soap noodle to produce. toilet soap the line capacity have 0-300 kg/h, 0-500 kg/h, 500-1000 kg/h. its a full set production line. including: mixer, 3 roller mill,single screw plodder,cutting machine,stamping machine and packing machine.

| Application | |

- Bread - layer cake | - Popsicle - Dumpling - drug |

Finished packaging sample photos

Soap production line

Soap production line use soap noodle to produce toilet soap bath soap hotel soap multi-pose soap. use soap noodle to produce. toilet soap the line capacity have 0-300 kg/h, 0-500 kg/h, 500-1000 kg/h. its a full set production line. including: mixer, 3 roller mill,single screw plodder,cutting machine,stamping machine and packing machine.

Bar Soap Making Machine Finishing Line

Process flow: Soap noodle → Mixing→ Grinding → Plodding → Cutting → Printing → Packing

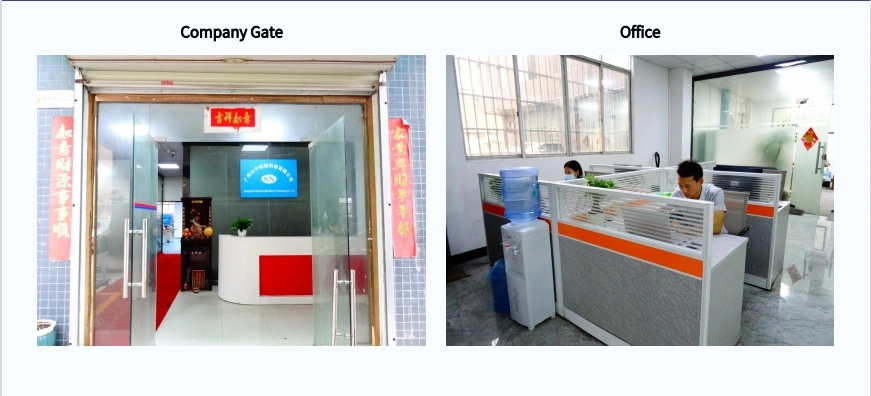

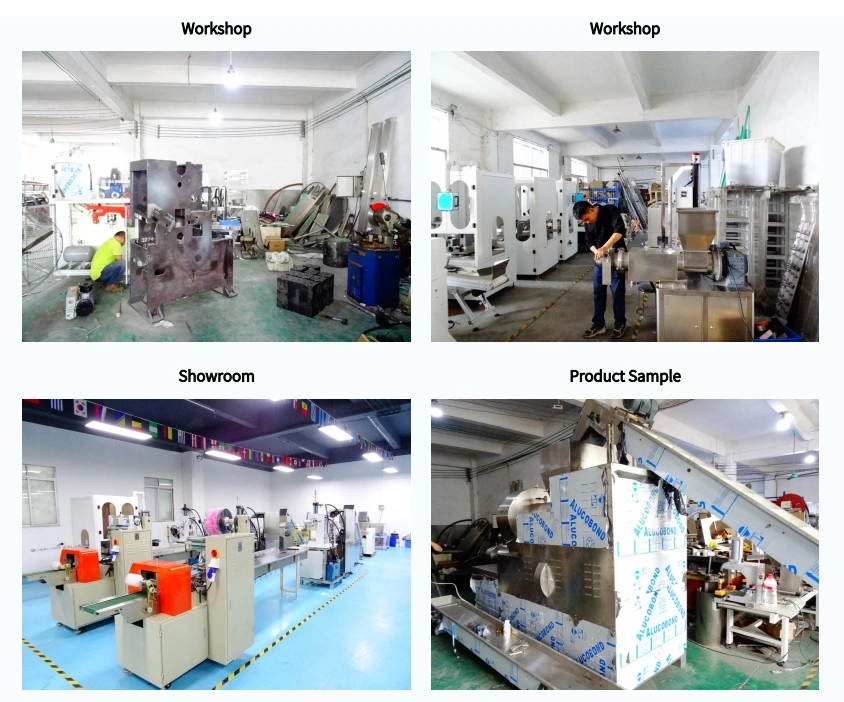

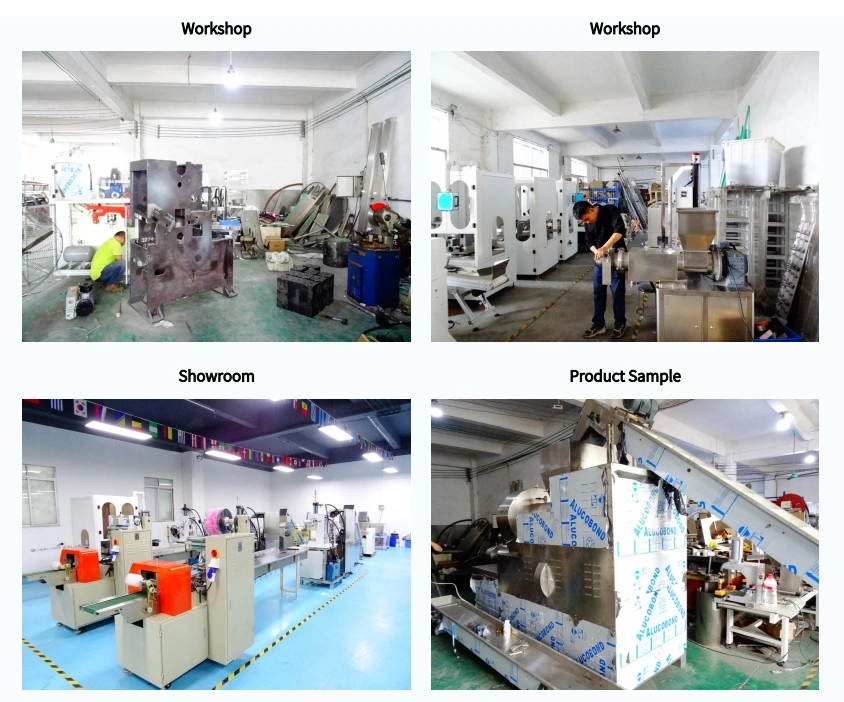

Factory Profile

Guangzhou Shanning Machinery Technology Co., Ltd. is a leading professional bath soap production line machinery and other dailly chemical and cosmetic filling line making machines factory from the China's famous manufacturing industry cluster with a thousand-year history and the world's first-tier, international business center province Guangdong Province,China.

Our factory have integrated R&D, production, sales and after-sale services for the bath soap production line machinery and other dailly chemical and cosmetic filling line making machines over 10 years. We have the rich experiences in bath soap production line machinery and other dailly chemical and cosmetic filling line making machines for manufacturing and production, absorbed abundant advanced technology in domestic and overseas, and continuously improves products' performance and quality.

With the advantages of safety, efficiency and stability, Shanning machinery is popular in the bath soap production line machinery and other dailly chemical and cosmetic filling line making machines in our domestic and overseas market.

In the future rapidly development, Guangzhou Shanning Machinery Technology Co., Ltd. Will continue to improve the quality of machines and improve the speed and efficiency of after-sale service to help and better service from all over the world new and old customers and partner, we sincerely welcome friendly partners and customers from all regions and countries around the world to visiting our factory and establishing long-term, stable and sustainable strategic partnerships for machines included: 1. Bath soap production line machines; 2. Automatic liquid filling line machines; 3. Non-standard machines,Thank you very much.

Why choose us

We can provide you with soap making equipment, soap making formula, process configuration, operation training, after-sales services and spare parts sales, as well as equipment maintenance, maintenance and other technical services, one-stop solution to your concerns, your one choice, we serve you for life, let you rest assured.

Our advantages Compared with peers, our factory has a professional R & D and design team. from material selection and processing to production,each process has professional quality inspection and control.provide you with better production equipment and increase production capacity. You can also customize the equipment according to

your needs, and the functions you want can be realized to truly solve your needs.

Packing & Shipping

Factory Profile

Guangzhou Shanning Machinery Technology Co., Ltd. is a leading professional bath soap production line machinery and other dailly chemical and cosmetic filling line making machines factory from the China's famous manufacturing industry cluster with a thousand-year history and the world's first-tier, international business center province Guangdong Province,China.

Our factory have integrated R&D, production, sales and after-sale services for the bath soap production line machinery and other dailly chemical and cosmetic filling line making machines over 10 years. We have the rich experiences in bath soap production line machinery and other dailly chemical and cosmetic filling line making machines for manufacturing and production, absorbed abundant advanced technology in domestic and overseas, and continuously improves products' performance and quality.

With the advantages of safety, efficiency and stability, Shanning machinery is popular in the bath soap production line machinery and other dailly chemical and cosmetic filling line making machines in our domestic and overseas market.

In the future rapidly development, Guangzhou Shanning Machinery Technology Co., Ltd. Will continue to improve the quality of machines and improve the speed and efficiency of after-sale service to help and better service from all over the world new and old customers and partner, we sincerely welcome friendly partners and customers from all regions and countries around the world to visiting our factory and establishing long-term, stable and sustainable strategic partnerships for machines included: 1. Bath soap production line machines; 2. Automatic liquid filling line machines; 3. Non-standard machines,Thank you very much.

Why choose us

We can provide you with soap making equipment, soap making formula, process configuration, operation training, after-sales services and spare parts sales, as well as equipment maintenance, maintenance and other technical services, one-stop solution to your concerns, your one choice, we serve you for life, let you rest assured.

Our advantages Compared with peers, our factory has a professional R & D and design team. from material selection and processing to production,each process has professional quality inspection and control.provide you with better production equipment and increase production capacity. You can also customize the equipment according to

your needs, and the functions you want can be realized to truly solve your needs.

Packing & Shipping

Customized export wooden box, thick plate, special sealing nails, plus reinforcement strips, professionals pack wooden box,shaking is very strong, packaging is strong, no need to worry about the wooden box falling apart in the middle.

FAQ

1.Are you a trading company or manufacturing plant?

We are the professional soap equipment manufacturing plant. We also produce all kinds of liquid soap and cosmetic production line equipment for over 1 decades years.

2.Why should you buy from us not from other suppliers?

Shanning Machinery is a professional corporation devoted herself to research, development, and manufacturing of all kind of soap machinery and equipment. The corporation owned a creative design and manufacturing team.

3,About the Voltage.

110V/220V/380V/415V,50/60HZ Single/three phase,customize the voltage according to your local voltage.

4.How to choose a suitable model?

Please tell us your capacity and raw materials, we will recommend the most suitable model for you .

5.How should I do if meet some trouble while using?

We supply 24 hours online service.Supply professional technical parameters, video picture sharing, project design.

6.About price.

It can be changed according to your quantity or package,so when you send a inquiry to me, please let me know your quantity, the price is negotiable .

7.About payment .

T/T ,Western Union; L/C at sight.

8.What is your terms of payment?

Payment term: 30% deposit in advance. 70% balance before delivery .

9.How to contact us ?

GUANGZHOU SHANNING MACHINERY TECHNOLOGY CO.,LTD.

1.Are you a trading company or manufacturing plant?

We are the professional soap equipment manufacturing plant. We also produce all kinds of liquid soap and cosmetic production line equipment for over 1 decades years.

2.Why should you buy from us not from other suppliers?

Shanning Machinery is a professional corporation devoted herself to research, development, and manufacturing of all kind of soap machinery and equipment. The corporation owned a creative design and manufacturing team.

3,About the Voltage.

110V/220V/380V/415V,50/60HZ Single/three phase,customize the voltage according to your local voltage.

4.How to choose a suitable model?

Please tell us your capacity and raw materials, we will recommend the most suitable model for you .

5.How should I do if meet some trouble while using?

We supply 24 hours online service.Supply professional technical parameters, video picture sharing, project design.

6.About price.

It can be changed according to your quantity or package,so when you send a inquiry to me, please let me know your quantity, the price is negotiable .

7.About payment .

T/T ,Western Union; L/C at sight.

8.What is your terms of payment?

Payment term: 30% deposit in advance. 70% balance before delivery .

9.How to contact us ?

GUANGZHOU SHANNING MACHINERY TECHNOLOGY CO.,LTD.

More information about this machine,Please feel free to contact us at any time!