Basic Info.

Model NO.

+86-13355139943

Method

Spray

Level

Finish Coat

Drying Method

Air Drying

Certification

ISO14001, CCC, RoHS, ISO9001

Substrate

Ceramic , Wood , Stone , Glass

Components

Film Forming Matter

Formation Mechanism

Conversion Type

Transport Package

200L Drum

Specification

A & B

Trademark

HIGHTOP

Origin

Shandong China

HS Code

3907299090

Production Capacity

5000000/Month

Product Description

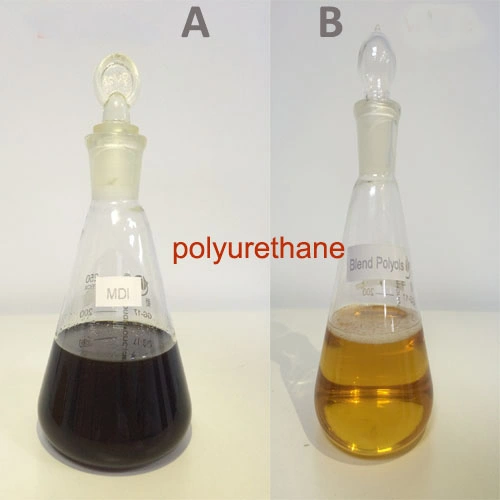

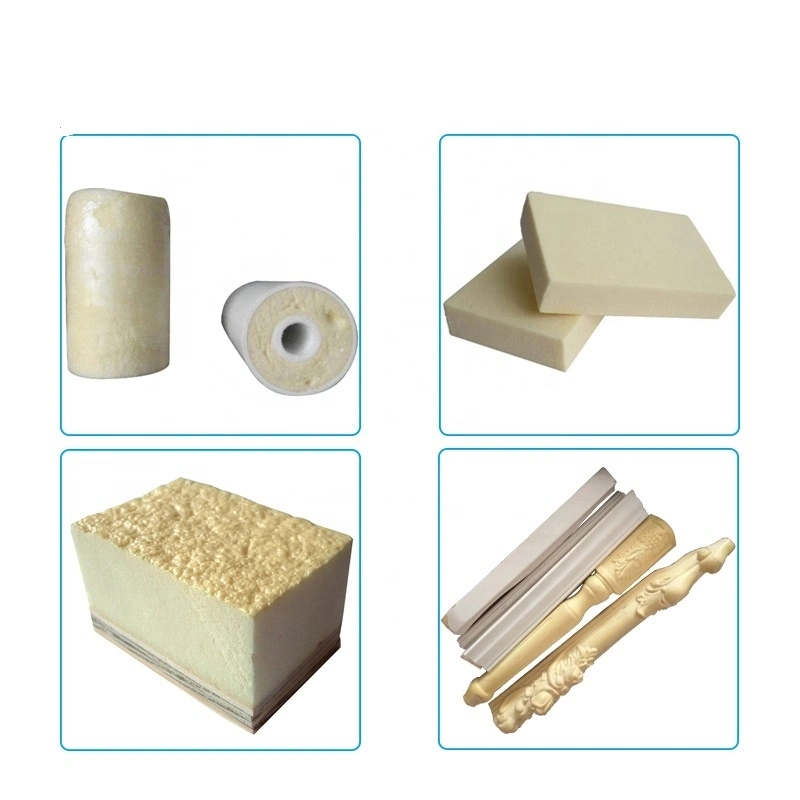

Polyurethane Spray Foam Closed Cell Pu Foam Chemicals Polyurethane Foam Pu Foam Injection Spray Foam

200L/drum, 4 drums per pallet, 80 drums for one 20ft container.

| Foam Performances | ||

| items | Test Method | Index |

| Spray Density | GB 6343 | >40kg/m3 |

| Closed-cell Rate | GB 10799 | ≥90% |

| Initial Thermal Conductivity(15ºC) | GB 3399 | ≤24mW/(m.K) |

| Compressive Strength | GB/T8813 | ≥150kPa |

| Adhesive Strength | GB/T16777 | ≥120kPa |

| Elongation at break | GB/T9641 | ≥10% |

| Dimentional Stability 24h -20ºC | GB/T8811 | ≤1% |

| 24h 70ºC | | ≤1.5% |

| Water Absorption | GB 8810 | ≤3% |

| Oxygen Index | GB 8624 | ≥26 |

Advantage of polyurethane spray foam insulation machine PU Foam Polyurethane insulation raw material 1. The cylinder solenoid valves are all imported, more expensive than the common cylinders. 2. Free on-line training for technology, full way tracking and testing, high sales volume. 3. All accessories are supplied by the original manufacturer and are available to customers at cost price 4. The high pressure pipe is anti-corrosion. 5. The temperature control meter is dual display, which can display the actual temperature and the set temperature. Other manufacturers can only display the set temperature and can not see the actual temperature. Red meter shows the actual temperature, green shows the set temperature 6. The operation temperature control panel is independent module which can be replaced separately. For other factories ,there is an integrated board next to the temperature control table,if one is broken ,others temerature meters all should be changed . Learn to maintain machine : Main Machine Daily Use and Maintenance: 1 Replace DOP in oil cup of primary-secondary pump daily; 2 When equipment stops running, swerve Start/Reset switch to reset direction, making sure cylinder rod fully soaked inside DOP liquid, in this way it can prolong service life of seal ring. 3 Check sensitivity of the equipment heating system, if anything goes wrong, please fix the problem as soon as possible. 4 When equipment isn't working, please turn off heating system timely, for not only it prevents potential danger also avoids low foaming quality cuz polyol material long-time heating. 5 Make sure turning on and off heating system in correct order. When turning on, first start main power,then turn on heating system; when turning off, first stopping heating system then turning off main power.