Basic Info.

Model NO.

JC-EPE-FM2000

Model

Jc-FM2000

Heating Method

Electricity,Oil Heating

Heating Power

15kw

Remark

with Trimming and Slitting

Working Width

2000mm

Transport Package

Packing by Film

Specification

1 set

Trademark

JC

Origin

China

HS Code

8477209000

Production Capacity

50sets/Month

Product Description

One-Side EPE Foam Laminating Machine Plastic Extruder Machine Suppplier

Description

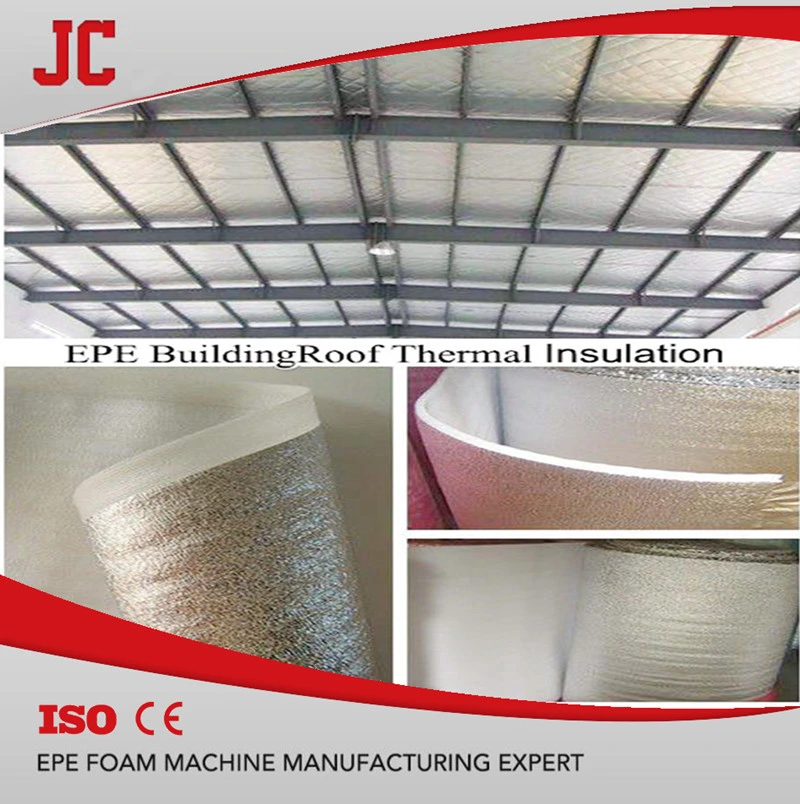

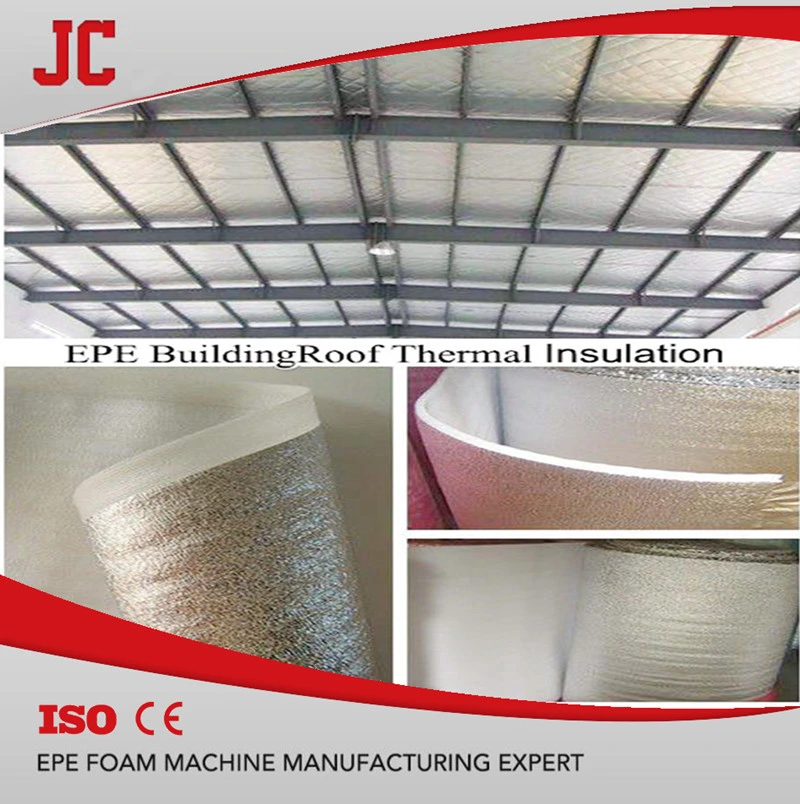

EPE foam sheet/film laminating machine ia mainly used for EPE roller with aluminum-coating film and color film by heating.The finished products are widely used in the bag-making,floor,decorative materials etc.

Major Specification

a. applicable material:

1) pe foam sheet

2) film or al roil

b. production capacity : 4800~6000m/hour

c. working width:1750mm

d. line speed: 40-60m/min

e. electrical supply power: 3¢×380v×50/60hz

Pre utilities

a. electrical power capacity: 16kw(approx)

b. used compressed air : 5-7 kg/cm

Detail spec .of machine

a . machine units

- framework : channel construction welded

-size of embossing heating roll:¢274*1750l

---grid: 1*1mm, 1.5*1.5mm, 3*3mm, 4*4mm

---round dot: 4mm, 5mm

-material of embossing heating roller: Seamless steel pipe

-emboss-roller pressing power: 10kg/cm2

-heating method:by circulation with hot-oil

-temperature of r/l:130-2500ºC

-tank-heater power:2kw×6 pcs

-size of rubber r/l: ¢274×1750l

-hardness of r/l:hs-a700

-cooling method of r/l:by water cooling

-winding method:by driving torque limiter

-driving type :by chain

-driving motor:VS 3hp×15 reducer

b . control units

a) for temperature control

-type:analogue system

b)for motor control

Spare parts list

1 spanner 1 pcs

2. hexagonal socket 1 set

3. heating tube 2 pcs

4. indication light 1 pcs

5. protective pipe 2 pcs

Specification

Company Profile

Our company was founded in 1996, factory area is around 95,000 square meter with fixed assets around 80 million, 600 workers and 120 experienced technicians. Annual output of plastic machinery is more than 3,000 sets and plastic products 50,000 tons. It is the first medium enterprise in western China to introduce the advanced technology from Germany, Italy, Japan and other countries to develop and innovate on the plastic machinery by themselves. It is the technical support unit of South China University of Technology-Polymer New Molding Equipment of National Engineering Research Center and the Nation Compound &modification Polymer Engineering and Technological Research Center.

JC group as the earliest company to make and innovate the plastic machinery in China is professional to make EPE foam board, sheet, pipe, rod, profile,net production line; CO2-XPS foam board production line; plastic netting machinery; EPP physical foam automobile interior board production line; EPE color-film coating machine; LDPE air bubble film machine, etc. Our domestic market share has been accounted for 70%. We also export to Turkey, Romania, Mexico, India, Indonesia, Malaysia, Thailand, Vietnam, Russia, the United States, etc.

We sticks to the principles of Quality First, Credibility First and Service Best to offer the best quality and most competitive price on the plastic machinery, warmly welcome the old and new customers to consult!

Why choose us

Jiecheng EPE Foam Production Line

1. Gurantee: 2 years

2. Delivery: 7-30 days

3. Absoluted No-wave EPE sheet & low density

4. CE, ISO certificates

5. Share 85% domestic market

6. Running foam machines all year round

Our company is specialized in EPE foam machines for 20 years and is the biggest manufucturer of EPE foam machine in China.We have qualitative products as well as professional sales and technical team, so we are able to provide customers with good products, excellent technical support and perfect after-sales service.

Contact

Description

EPE foam sheet/film laminating machine ia mainly used for EPE roller with aluminum-coating film and color film by heating.The finished products are widely used in the bag-making,floor,decorative materials etc.

Major Specification

a. applicable material:

1) pe foam sheet

2) film or al roil

b. production capacity : 4800~6000m/hour

c. working width:1750mm

d. line speed: 40-60m/min

e. electrical supply power: 3¢×380v×50/60hz

Pre utilities

a. electrical power capacity: 16kw(approx)

b. used compressed air : 5-7 kg/cm

Detail spec .of machine

a . machine units

- framework : channel construction welded

-size of embossing heating roll:¢274*1750l

---grid: 1*1mm, 1.5*1.5mm, 3*3mm, 4*4mm

---round dot: 4mm, 5mm

-material of embossing heating roller: Seamless steel pipe

-emboss-roller pressing power: 10kg/cm2

-heating method:by circulation with hot-oil

-temperature of r/l:130-2500ºC

-tank-heater power:2kw×6 pcs

-size of rubber r/l: ¢274×1750l

-hardness of r/l:hs-a700

-cooling method of r/l:by water cooling

-winding method:by driving torque limiter

-driving type :by chain

-driving motor:VS 3hp×15 reducer

b . control units

a) for temperature control

-type:analogue system

b)for motor control

Spare parts list

1 spanner 1 pcs

2. hexagonal socket 1 set

3. heating tube 2 pcs

4. indication light 1 pcs

5. protective pipe 2 pcs

Specification

| Model | JC- EPE-FM1300 | JC- EPE-FM1500 | JC- EPE-FM1750 | JC- EPE-FM2000 | JC- EPE-FM2200 | JC- EPE-FM2500 | |

| Working width | mm | 1200 | 1300 | 1500 | 1800 | 2000 | 2400 |

| Heating method | Electricity, oil heating | ||||||

| Heating power | KW | 12 | 12 | 12 | 15 | 15 | 18 |

| Remark | With trimming and slitting | ||||||

Company Profile

Our company was founded in 1996, factory area is around 95,000 square meter with fixed assets around 80 million, 600 workers and 120 experienced technicians. Annual output of plastic machinery is more than 3,000 sets and plastic products 50,000 tons. It is the first medium enterprise in western China to introduce the advanced technology from Germany, Italy, Japan and other countries to develop and innovate on the plastic machinery by themselves. It is the technical support unit of South China University of Technology-Polymer New Molding Equipment of National Engineering Research Center and the Nation Compound &modification Polymer Engineering and Technological Research Center.

JC group as the earliest company to make and innovate the plastic machinery in China is professional to make EPE foam board, sheet, pipe, rod, profile,net production line; CO2-XPS foam board production line; plastic netting machinery; EPP physical foam automobile interior board production line; EPE color-film coating machine; LDPE air bubble film machine, etc. Our domestic market share has been accounted for 70%. We also export to Turkey, Romania, Mexico, India, Indonesia, Malaysia, Thailand, Vietnam, Russia, the United States, etc.

We sticks to the principles of Quality First, Credibility First and Service Best to offer the best quality and most competitive price on the plastic machinery, warmly welcome the old and new customers to consult!

Why choose us

Jiecheng EPE Foam Production Line

1. Gurantee: 2 years

2. Delivery: 7-30 days

3. Absoluted No-wave EPE sheet & low density

4. CE, ISO certificates

5. Share 85% domestic market

6. Running foam machines all year round

Our company is specialized in EPE foam machines for 20 years and is the biggest manufucturer of EPE foam machine in China.We have qualitative products as well as professional sales and technical team, so we are able to provide customers with good products, excellent technical support and perfect after-sales service.

Contact