- Overview

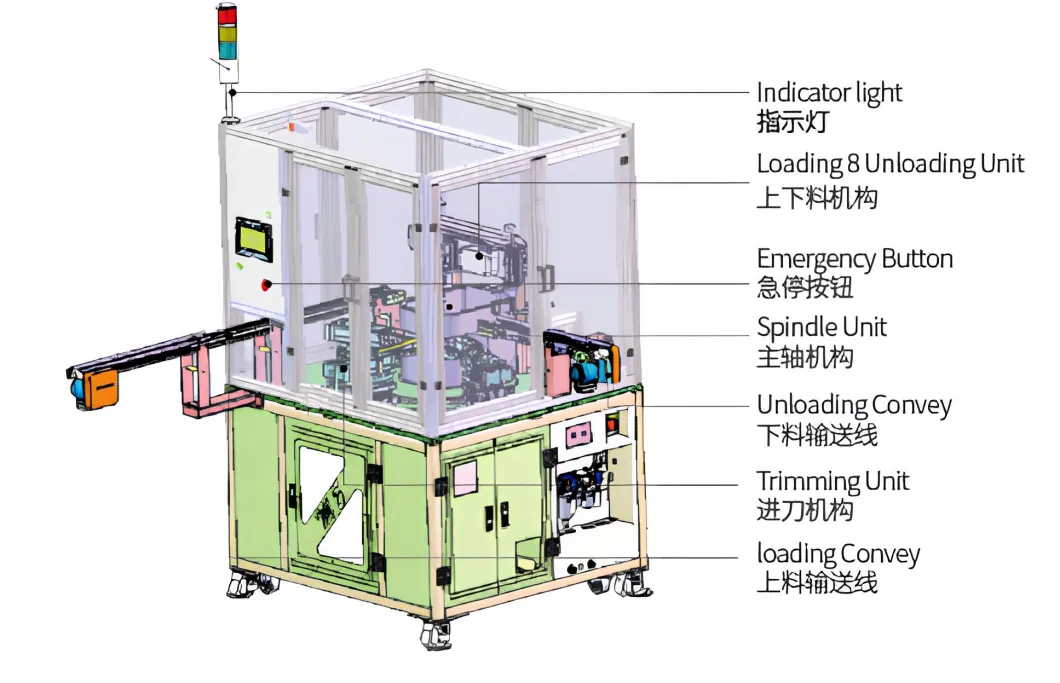

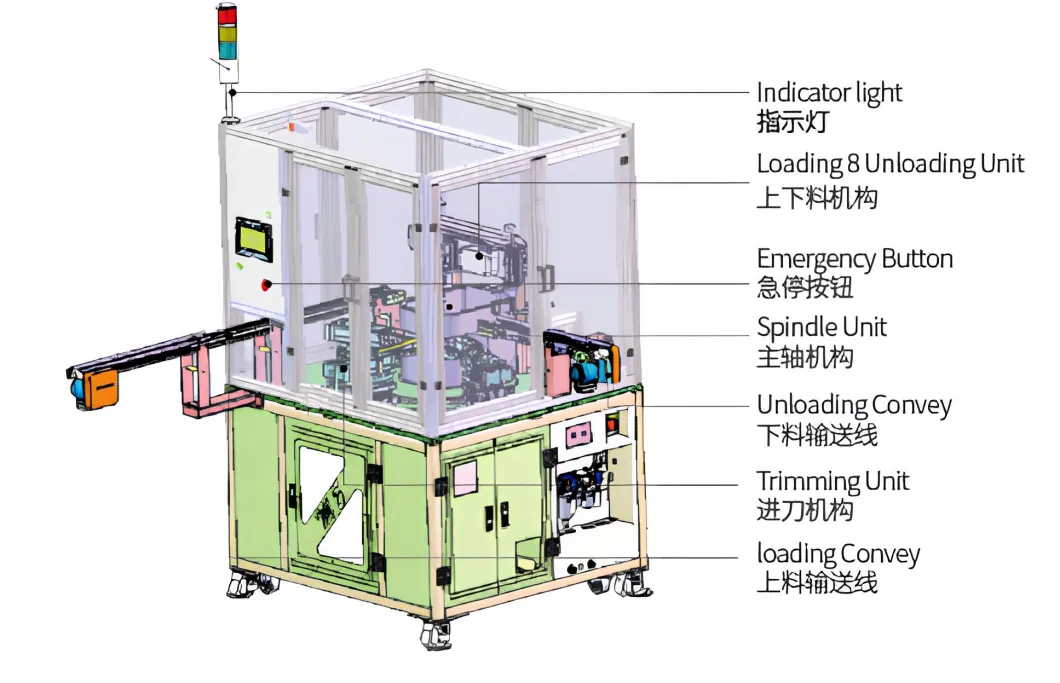

- Product Description

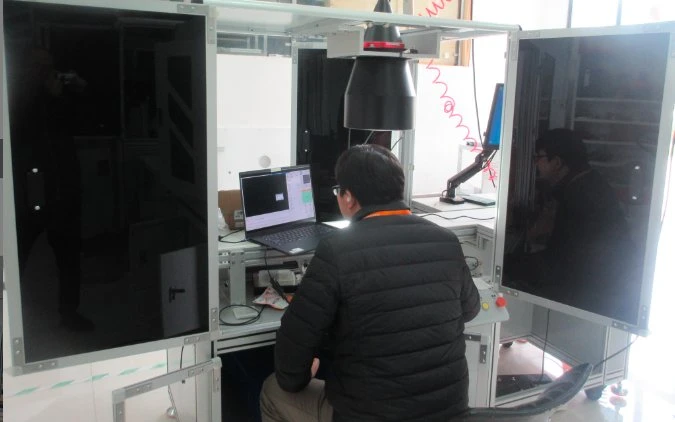

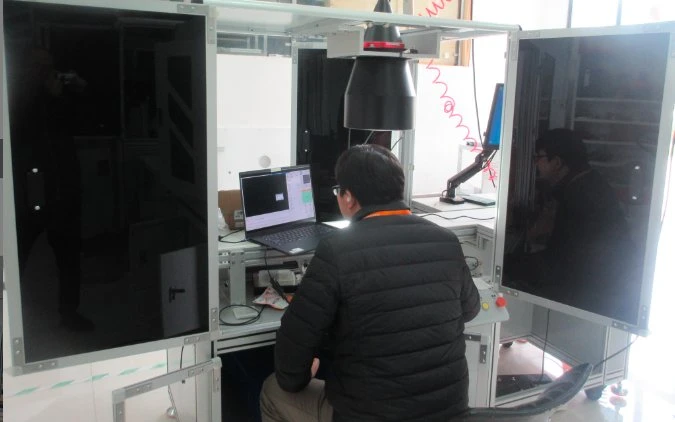

- Detailed Photos

- Product Parameters

- Packaging & Shipping

- Installation Instructions

- Company Profile

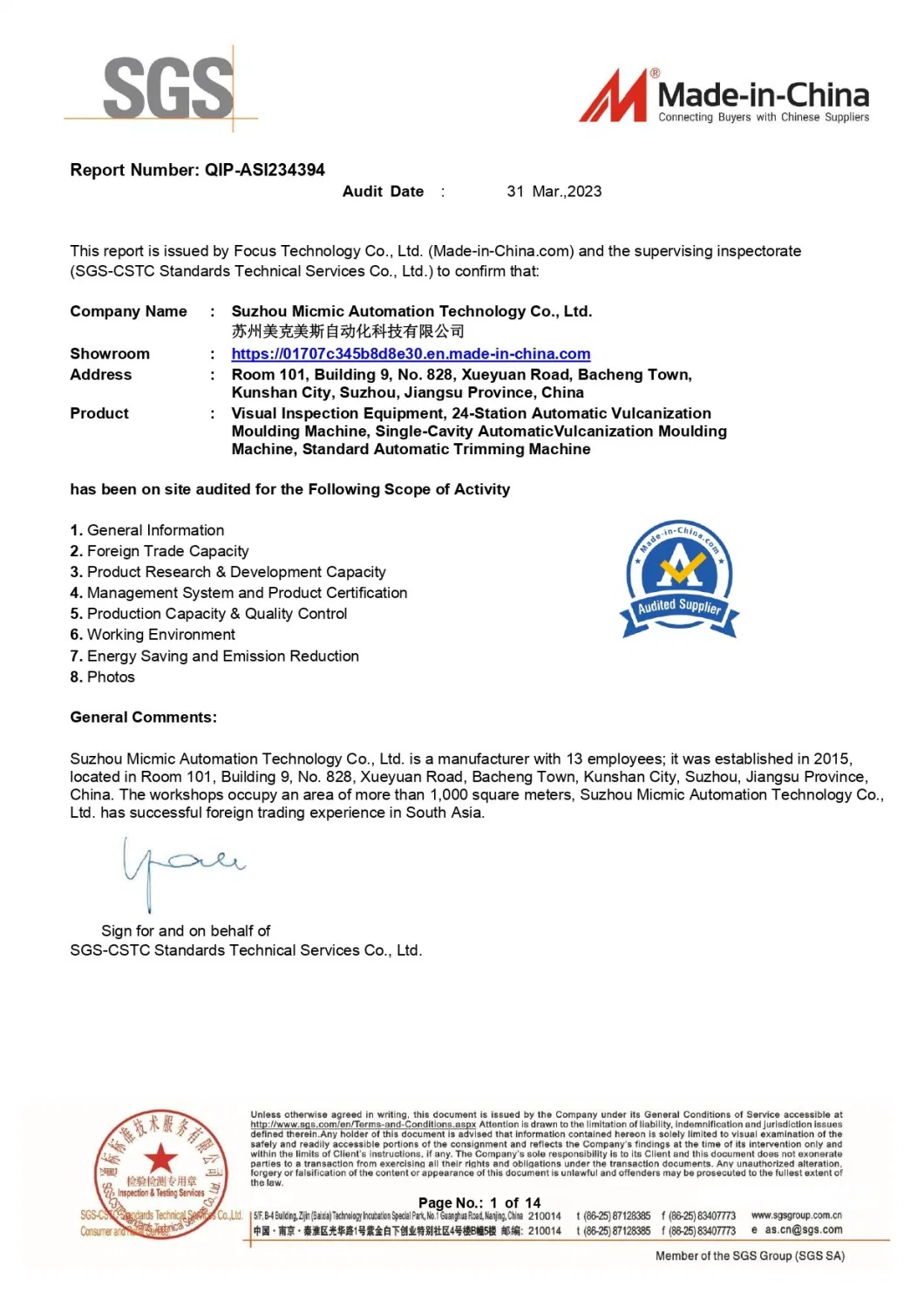

- Certifications

- Our Advantages

Basic Info.

Model NO.

MIC20-TR01

Can It Be Processed and Customized

Yes

Transport Package

Wooden Box

Specification

1200*1200*2000

Trademark

MICMIC

Origin

Kunshan, Jiangsu

HS Code

8458110090

Production Capacity

500PCS/Year

Product Description

https://szmicmic.en.made-in-china.com/product/AEtRDTcUFehY/China-Automatic-Punching-and-Loading-Machine-Automotive-Trimming-Rubber-Automation-Machine.html

Founded in 2015,SUZHOU MICMIC AUTOMATION TECHNOLOGY CO., LTD is situated in Kunshan, a county-level city that has consistently held the top economic ranking in China for 18 consecutive years. We are a high-tech enterprise specializing in the research, development, manufacturing, and sales of cutting-edge automation equipment. With extensive experience and mature integrated solutions in the rubber and plastic industries, our company has achieved steady growth over the years. Our equipment is distributed across major provinces and cities in China and exported to Europe, America, and Southeast Asia regions.

Founded in 2015,SUZHOU MICMIC AUTOMATION TECHNOLOGY CO., LTD is situated in Kunshan, a county-level city that has consistently held the top economic ranking in China for 18 consecutive years. We are a high-tech enterprise specializing in the research, development, manufacturing, and sales of cutting-edge automation equipment. With extensive experience and mature integrated solutions in the rubber and plastic industries, our company has achieved steady growth over the years. Our equipment is distributed across major provinces and cities in China and exported to Europe, America, and Southeast Asia regions.

Main Products:Cold Feed Preformer,Multi-Station & Single Cavity Moulding,Automatic trimming machine,Automatic punching and loading machinepunching and loading machine, air-tightness detector, Automatic O-ring detection machine,automatic sealing bag packaging machines, and other customized automatic equipment.

Our goal is to maximize customer benefits.

Business Philosophy: Pursuing innovation, Fostering communication, Embracing teamwork, Driving optimization, and Continuous improvement.

Advantages of the integrated solution: Fully automated, promoting strong sustainability.

We have rich experience and mature solutions in production and testing technology.

Our company's products are widely used in rubber products, sealing products, alloy products, precision metal parts, etc., for production, quality testing, packaging, improving customer part efficiency and quality, and helping customers occupy the market

Items:

Parts surface and dimensions with different materials and shapes can be Production &inspected

Not limited to product testing as shown in the diagram, customizable according to customer needs

Parts surface and dimensions with different materials and shapes can be Production &inspected

Not limited to product testing as shown in the diagram, customizable according to customer needs

| Type | MIC20-TR01 | MIC20-TR01 | MIC20-TR01 | MIC20-TR01 | MIC20-TR01 |

| Model | 3D80 | 2D80 | 1D80 | 3D140 | 2D140 |

| OD Max (mm) | 80 | 80 | 80 | 140 | 140 |

| Knife Qty. | 3 | 2 | 1 | 3 | 2 |

| Axis Run-out mm | 0.02 | 0.02 | 0.02 | 0.02 | 0.02 |

| Tooling run-out mm | 0.04 | 0.04 | 0.04 | 0.06 | 0.06 |

| Size | 1040x 1030 x 2000 | 1040x1030 x2000 | 1040x1030 x200 | 1200x1200x2000 | 1200x1200x2000 |

| Weight (T) | 0.5 | 0.5 | 0.5 | 0.6 | 0.6 |

| Power (KW) | 2.5 | 2.4 | 2.3 | 2.5 | 2.4 |

| Gas consumption (L) | 60 | 60 | 60 | 60 | 60 |

| Voltage (V) | 220 | 220 | 220 | 220 | 220 |

| Gas (Bar) | 5-6 | 5-6 | 5-6 | 5-6 | 5-6 |

Advantage:

*Customized equipment can be designed according to the product

*Nice compatibility with SCM and AVI system.

*Auto loading and unloading, on-line cooling.

*3 knives (optional),Electric cylinder driving, Easily adjustable speed.

*2 heads, trimming and loading simultaneously, improving efficiency.

*Fast cycle; 4s/pcs for de-flashing and 4.5s/pcs for main lip.

*Small footprint

*Low noise

*Convenient

*Link to MES

Packaging method: Non fumigation wooden box packaging

Transportation: Sea freight (designated by Party A)

Transportation: Sea freight (designated by Party A)

Engineer on-site installation and debugging

Equipment operation training

Equipment maintenance training

Equipment maintenance training

Equipment operation training

Equipment maintenance training

Equipment maintenance training

About us

Main Products:Cold Feed Preformer,Multi-Station & Single Cavity Moulding,Automatic trimming machine,Automatic punching and loading machinepunching and loading machine, air-tightness detector, Automatic O-ring detection machine,automatic sealing bag packaging machines, and other customized automatic equipment.

Our goal is to maximize customer benefits.

Business Philosophy: Pursuing innovation, Fostering communication, Embracing teamwork, Driving optimization, and Continuous improvement.

Suzhou Micmic Automation Technology Co., Ltd. is a manufacturer with 13 employees; it was established in 2015, located in Room 101, Building 9, No. 828, Xueyuan Road, Bacheng Town, Kunshan City, Suzhou, Jiangsu Province, China. The workshops occupy an area of more than 1,000 square meters, Suzhou Micmic Automation Technology Co., Ltd. has successful foreign trading experience in South Asia.

Since its establishment, the company has a number of patents & software works, and has rich experience and solutions in the industry.

Fully Integrated Automatic Solution for Rubber and Plastic Components

Advantages of the integrated solution: Fully automated, promoting strong sustainability.